link. This was done to prevent the torquing

from being missed if you were only per-

forming one of the many operations that

require you to remove and replace the yoke

and plate. If you have performed all the

operations described, then, at this time, you

do the final torquing before the suspension

lines are placed into the container. There-

fore, it is very important that you complete

this process in the following manner and have it

inspected.

Remove the yoke and plate assembly on the

outboard top connector link located on the

helper’s side. Insert the connector link bar through

the loop in the firing lanyard and reattach the

yoke and plate assembly. Tighten the screw to a

torque value of 20 to 25 pound-inches. Apply a

tamper dot to the connector link screwhead using

lacquer (TT-L-32, color 11136, insignia red or

equivalent).

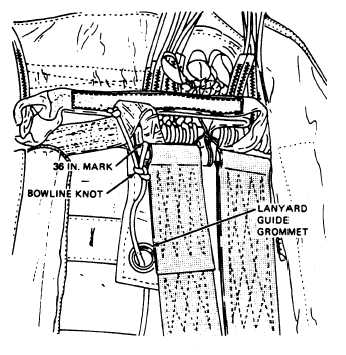

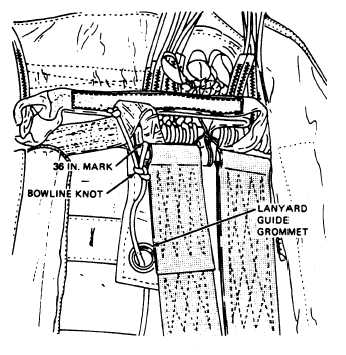

Figure 3-33.—Reeving release lanyard.

As you have read this chapter on the NES-12,

you may have noticed that each time you have

removed the yoke and plate assembly from the

connector link, you have been told to tighten and

torque the screw when reassembling the connector

At this point, you have completed the

rigging and you are ready for the packing

procedure.

When actually performing any of these

procedures, you should refer to the NAVAIR

13-1-6.2 and NAVAIR 13-600-4-6-3. Also, you

will find that some of your rating exam questions

will be taken from these NAVAIR manuals.

3-15