Installation

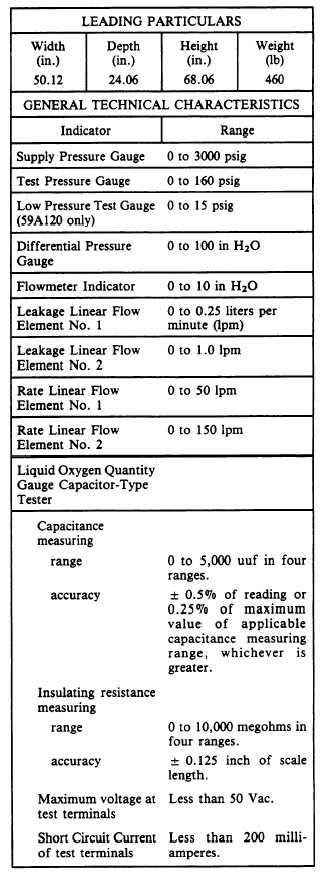

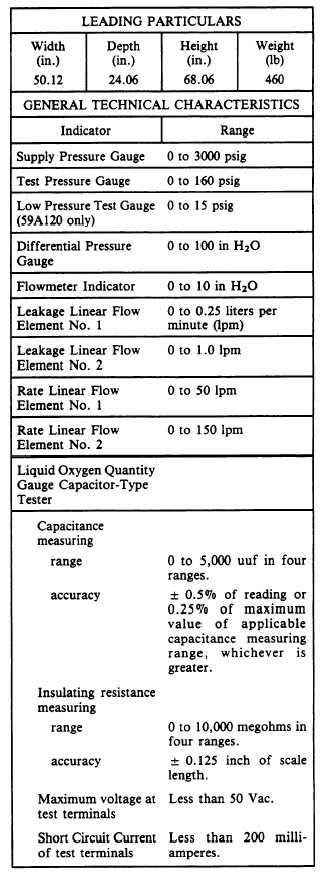

Table 11-1.—Test Stand Installation

The test stand may be installed in any

convenient location. Table 11-1 includes nominal

dimensions of the test stand. Total space

requirements can be determined by adding a

reasonable working area to the dimensions given

in the table.

NOTE: The test stand has drilled flanges

to allow stable mounting. If shock pads are

placed under the stand, they must extend

under the whole stand to give even distribu-

tion of support.

Power requirement for the test stand is 115

Vat, 400-cycle, single-phase service. The test stand

is connected to a suitable power source by the

electrical cable assembly.

A 300 to 2,000 psig oxygen source is required.

A metal strap on the left rear of the test stand

is provided for mounting and securing the oxygen

supply cylinder.

Visual Inspection

Visually inspect the test stand for the

following:

1. Dial glasses for cracks or breakage

2. All hoses for cracks or breaks

3. All pipe and hose fittings for security of

connection, worn, stripped or crossed threads

4. All tubing for severe dents or punctures

5. All valves for body cracks

6. Heat exchanger for rupture, severe dents,

or punctures

7. Gauge tester for damaged or loose parts,

and tightness of terminals and connectors

Any components found to be damaged or

defective should be repaired or replaced. Refer

to NAVAIR 17-15BC-20 for part numbers.

Test Stand Leakage Tests

Test stand leakage tests are performed by

personnel attached to the oxygen shop and

consist of setting the oxygen pressure regulator,

leak testing the accessories section, test stand

section, and Bell Jar assembly.

SETTING THE OXYGEN PRESSURE

REGUIATOR.— To set oxygen pressure regulator

11-18