The Mk 7 arresting engines have an 18:1 reeve

ratio, which means for every foot of ram travel there are

18 feet of purchase cable payout. The number of

sheaves on the crosshead determines the reeve ratio.

The types of reeves used on the Mk 7 arresting engines

are 18:1 single reeve on pendant engines, and 18:1

endless reeve on barricade engines. The endless reeve

barricade engines use only one purchase cable with the

two bitter ends terminating on the flight deck and

connected to the barricade. The single-reeved pendant

engines require two purchase cables, one reeved around

the 28-inch pitch diameter sheaves and one reeved

around the 33-inch pitch diameter sheaves of the fixed

sheave and crosshead assemblies.

FAIRLEAD SYSTEM SHEAVES

Three types of sheaves are used in Mk 7 arresting

gear. They are the horizontally mounted retractable

sheave, the vertical through-deck sheave, and the

fairlead sheave. All these sheaves are designed to

accommodate 1 7/16-inch diameter purchase cable and

are made of forged aluminum alloy.

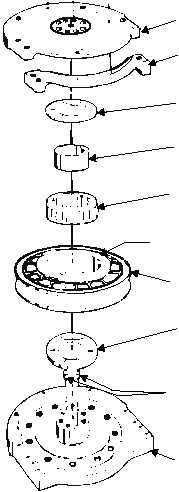

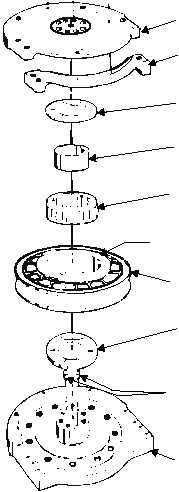

A typical sheave includes a base and cover that

retains the sheave assembly. See figure 3-27. Two

grease fittings provide access for lubricating the sheave

bearing and spacers. The sheave assembly has three

races: an inner race, a bearing race, and an outer race.

Mounted with each sheave is a two-piece concentric

spacer. The inner spacer is made of steel and is the

lubricant distributor. The outer spacer, made of

phenolic, is bonded to the sheave, provides a bearing

surface, and is a lubricant retainer for the sheave. The

horizontal and vertical sheaves are identical except for

their mounting arrangement.

The function of a retractable sheave is to provide a

means of lowering deck sheaves that would interfere

with the passage of aircraft and deck equipment when

in the raised operating position. Figure 3-28 is an

example of a retractable sheave installation.

Each retractable sheave is operated by an electric

motor unit controlled by a deckedge push-button

station. In addition, an indicator light box is installed

adjacent to the deckedge push-button station to show

the position of the sheave—a green light when the

sheave is fully raised, or a red light in all positions other

than fully raised. The retractable sheaves may also be

operated

by

means

of

handwheels

in

case

of

emergency. The handwheel is located below decks on

the operating unit. To eliminate the chance of the

retractable sheave being lowered inadvertently during

landing operations, the handwheel is removed from the

unit whenever it is not actually being used.

The retractable sheave operating unit is bolted to

the bottom of the retractable sheave assembly. It is

accessible for maintenance and manual operation from

the compartment that is directly below the retractable

sheave.

The

retractable

sheave

operating

unit

is

a

self-contained unit consisting of a high-torque electric

motor, a geared drive system, and limit switches. See

figure 3-29.

The motor is coupled to the wormshaft, which has a

worm splined to the shaft. The worm engages the worm

gear, which is free to rotate on the sleeve. There are two

lugs on the back of the worm gear that, after some free

rotation, engage two lugs on the back of the clutch

bevel gear. The free rotation is to prevent putting an

immediate load on the electric motor. The clutch bevel

gear is splined to the sleeve, so that any rotation of the

clutch bevel gear rotates the sleeve.

3-28

ABEf0327

COVER

INSERT

INNER

SPACER

INNER

RACE

OUTER SPACER

(BONDED)

SHEAVE

INNER

SPACER

GREASE

FITTINGS

BASE

BEARING

RACE

Figure 3-27.—Typical sheave assembly.