core, within which is contained a paper or plastic tape

strip bearing the name of the wire rope manufacturer.

The function of the oiled hemp center is to provide a

"cushion" for each strand and also to supply lubrication

when the cable is under tension. The deck pendant

cable ends are equipped with swaged-type terminals.

These terminals are pinned to the clevis and socket

assembly at the purchase cable coupling for quick

detachment during replacement.

To remove a pendant, it is necessary to put slack in

the cable. If the pendant has been retrieved and must be

replaced, reduce the accumulator pressure to 200 psi

and pull the pendant out a few feet, using a deck tractor.

Hold the retracting valve open while the tractor is

pulling, then block the valve in the closed position to

prevent retraction. It may be necessary to clamp a block

on the purchase cable to prevent its slipping back due to

its own weight. If a pendant is badly damaged during an

arrestment and must be replaced immediately, either do

NOT retract the pendant or retract the pendant only

partially so that slack is left in the cable system.

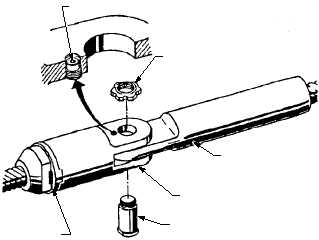

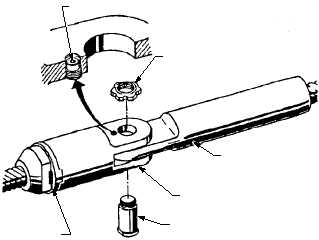

Refer to figure 3-32, and perform the following

task to replace a deck pendant. Screw the lockscrew

into the clevis end socket, remove the anchor nut and

pull out the clevis pin. Secure the eye end of the

terminal of the new deck pendant to the clevis end

socket of the purchase cable socket assembly by means

of the clevis pin, anchor nut, and the lockscrew.

Recharge the accumulator and retract the engine.

Deck pendants are provided as assemblies—not

made up on board ship. Suitable handling facilities

should be available. Spare pendants should be

conveniently stowed, ready for quick rigging, since

replacement of a deck pendant is sometimes an

emergency procedure that must be performed quickly.

The replacement operation can best be performed

by four separate crews. One crew is needed to pull out

the pendant, one at each of the two couplings, and one

to bring the new pendant on deck and roll it out and in

position.

Impact Pads

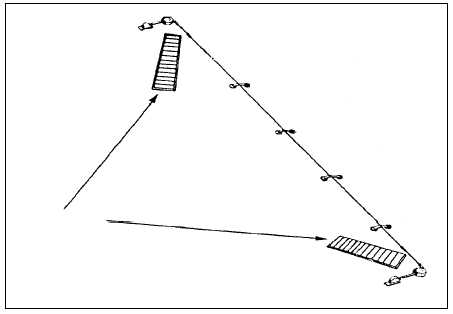

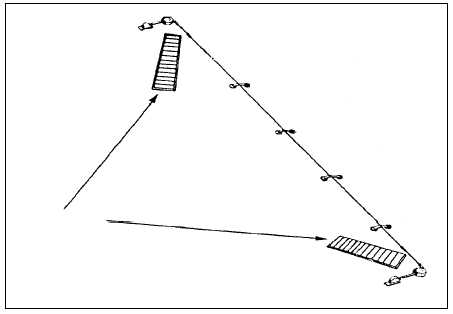

Impact pads (fig. 3-33) are made up of several

sections of polyurethane pads laid side by side and

secured within an outer steel frame. The frame is both

3-32

LOCKSCREW

ANCHOR NUT

DECK PENDANT

TERMINAL

CLEVIS SOCKET

CLEVIS PIN

TACK WELD

ABEf0332

Figure 3-32.—Deck pendant terminal and clevis socket

assembly.

IMPACT PADS

ABEf0333

Figure 3-33.—Terminal impact pads.