the worm gear on the sleeve. The worm gear rotates

freely on the sleeve for part of the rotation, thus

permitting the motor to gain speed before full loading.

As the worm gear rotates, the lugs on its face engage the

lugs on the face of the clutch bevel gear. Rotation of the

clutch bevel gear, which is splined to the sleeve, rotates

the sleeve, which is directly connected to the screw of

the retractable sheave, thus raising the sheave. When

the sleeve rotates, the limit bevel gear, keyed to the

sleeve, rotates to turn the pinion of the geared limit

switch. This is the only function of the limit bevel gear.

When a predetermined point is reached by the rotor of

the geared limit switch, the RAISE circuit is broken and

the raising operation ceases. As the geared limit switch

is actuated, the green lamp (sheave UP lamp) will light

in the deckedge light box.

Energizing the motor to lower the retractable

sheave, by depressing the LOWER push button, causes

the motor and the drive system to operate in the reverse

direction. Again there is free rotation until the lugs on

the worm gear make a complete revolution before

striking the other side of the lugs on the clutch bevel

gear. The sheave lowers until it is completely seated and

opens the torque limit switch to break the motor circuit.

If an obstruction prevents the sheave from descending,

the worm, which is still rotating because of the force of

the motor, does not turn the worm gear. The worm is

driven axially along the wormshaft until the torque

limit switch is opened by the tripping plate washer. The

torque limit switch may be adjusted to permit the

sheave to seal with a predetermined force before the

circuit is interrupted. The torque spring then absorbs

the remaining inertia of the system after the circuit is

broken. During the time the sheave is lowered and

raised up until the time the RAISE geared limit switch

is tripped, the red (sheave NOT UP) lamp glows on the

deckedge light box.

For manual operation, the handwheel must be

mounted on its shaft and secured to the shaft with a

setscrew. The declutch lever must then be thrown in a

counterclockwise direction. This movement will slide

the clutch bevel gear along the splined section of the

sleeve to engage a gear on the handcrank shaft. When

the handcrank is turned, the sleeve turns, rotating the

sheave screw to raise or lower the sheave. The declutch

lever remains in the clutch position until operation

under motor power is resumed, at which time the

handwheel is disconnected automatically by the clutch

trippers. There is no danger to an operator if he or she is

turning the handwheel when the motor is started,

because the handwheel is disengaged instantly without

shock or jolt.

Thru-deck Sheave

The thru-deck sheave (fig 3-23) is mounted

vertically and it guides the purchase cable between the

sheave damper and the retractable sheave installation.

Fairlead Sheaves

Fairlead sheaves (fig. 3-23) are single sheaves that

are installed at points in the drive system where the

purchase cable require a change of direction. The

number of fairlead sheaves varies based on engine

location in relation to the location of the anchor and

sheave dampers.

Crossdeck Pendants

The polyester-core crossdeck pendant are made of

1 7/16-inch diameter, 6 × 30 flattened strand polyester

core construction with no filler wires, all wires are

considered loading bearing with a minimum breaking

strength

of

205,000

pounds.

To

differentiate

polyester-core

CDPs

from

sisal-core

CDPs

the

polyester-core terminals have a groove around the end

where the cable enters the terminal. The deck pendant

cable ends are equipped with swaged-type terminals.

These terminals are pinned to the clevis and socket

assembly at the purchase cable coupling for quick

detachment during replacement.

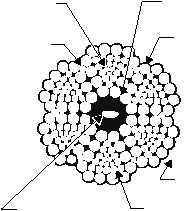

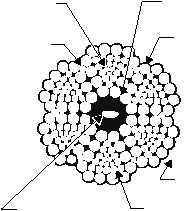

The sisal-core crossdeck pendant are made of

1 3/8-inch diameter, 6 × 30 flattened strand construc-

tion, preformed, uncoated lang lay wire rope with a

minimum breaking strength of 188,000 pounds. Each

wire rope is made up of 6 steel strands, each of which is

a bundle of 12 major and 12 intermediate wires twisted

around a triangular core of 3 to 9 wires. (See fig. 3-31.)

The strands are twisted about an oiled-hemp center

3-31

TRIANGULAR

CORE

CORE

(HEMP, FIBER)

12 MAJOR

WIRES

6 STRANDS

PER CABLE

12 INTERMEDIATE

WIRES

MANUFACTURER'S

IDENTIFICATION TAPE

INTERFACE

2

1

6

5

4

3

ABEf0331

Figure 3-31.—Cross section of preformed sisal core 6 × 30

crossdeck pendant.