arrestment with four exceptions: (1) no fluid coolers are

installed, (2) barricade engines are endless reeved, (3)

no anchor dampers are installed, and (4) a short-stroke

control valve cam is used on most carriers.

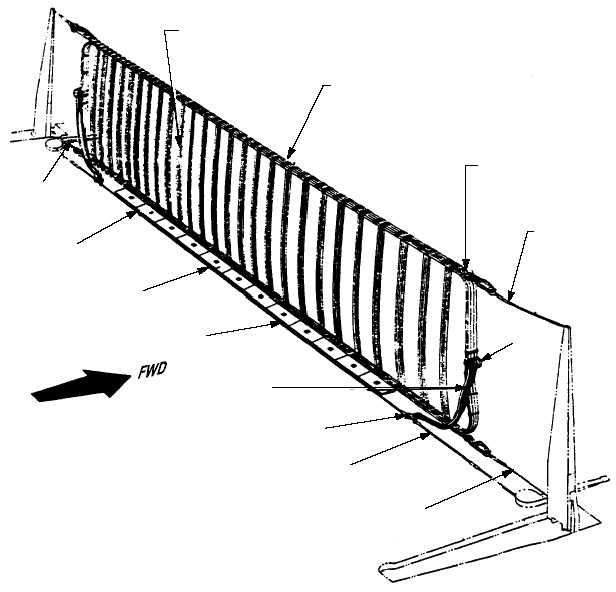

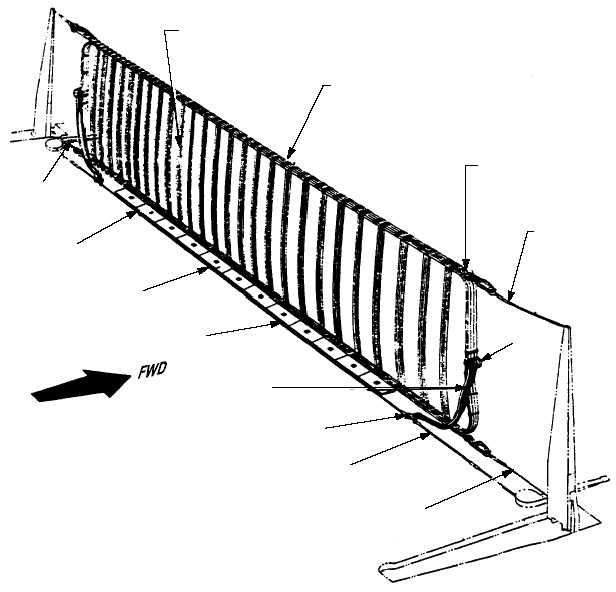

BARRICADE WEBBING ASSEMBLY

Since

barricade

arrestments

are

emergency

situations, barricade-rigging operations must be swift

and efficient. The barricade webbing assemblies (fig.

3-36) are assembled and stored in an area where the

webbing assemblies will be readily accessible when an

emergency situation arises. The barricade storage room

is equipped with a rack designed to stow three

barricades simultaneously:

READY— Jet Barricade

STANDBY— Jet Barricade

PRACTICE— Jet Barricade

The E2/C2 barricade is also stowed in the stowage

room. The storage area for the webbing assemblies

must be dry and must protect the webbing from

exposure to direct sunlight. The effects of water on a

barricade webbing assembly will result in the loss of

approximately 10 to 15 percent of the webbing's

strength and its weight increases by approximately 40

to 45 percent. However the strength loss and increase in

weight are not permanent. When the webbing is dry to

the touch the original barricade strength and weight are

regained .

3-35

ENGAGING STRAPS

ANCHOR

HOLDDOWN

DECK RAMP

PARALLEL

PENDANT

SHACKLE

ASSEMBLY

EXTENSION PENDANT

EXTENSION LOOP

CONNECTING

STRAP

MULTIPLE RELEASE

STRAPS

UPPER TENSIONING

PENDANT

(DECK GEAR)

LOWER TENSIONING

PENDANT

(DECK GEAR)

THREE WEBBING ASSEMBLIES

(MODIFIED 91' ASSEMBLIES,

REGULAR 108' ASSEMBLIES OR

A MIXTURE OF EACH)

ABEf0336

Figure 3-36.—Barricade webbing installation.