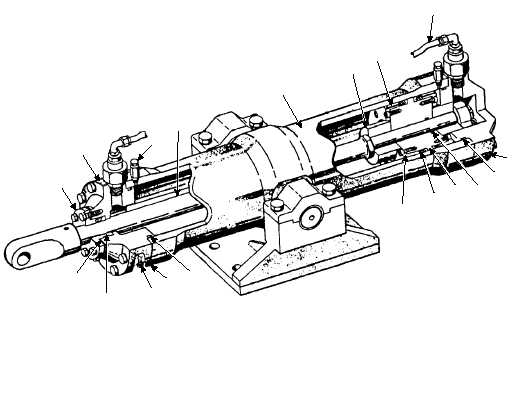

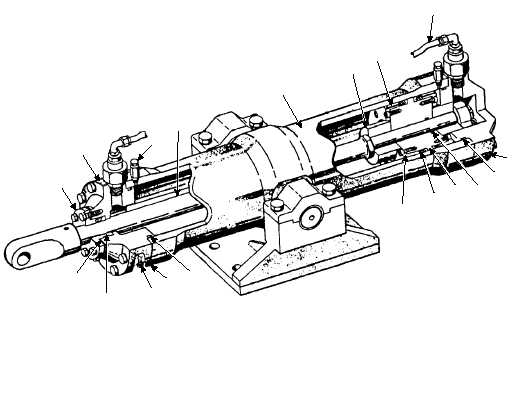

glands (11) secured by bolts, each safety wired. Shims

(14) are provided between the piston face and piston

gland to obtain the proper packing float. The piston rod

is sealed where it extends through the front cap (3) by

four V-ring packings (12), a spacer, and piston rod

gland (10) secured by bolts and washers. Shims (14) are

provided to obtain proper packing float. A terminal is

attached to the end of the piston rod and is secured by a

setscrew. The front cap and rear face are each fitted with

a tailpiece, an adapter, an orifice plate, a union nut, and

an elbow to attach hose; joints are sealed by O-rings

and packing. A vent valve assembly (8) and plug (9) are

located at each end of the hydraulic cylinder to vent air

or drain fluid.

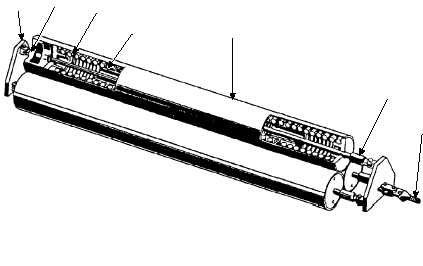

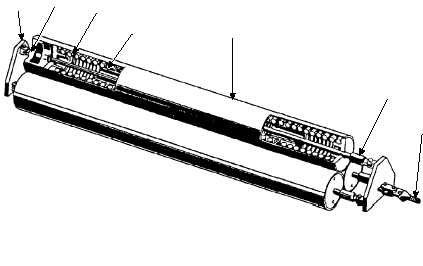

COUNTERBALANCING SPRING

The counterbalancing spring supplements the force

of the stanchion cylinder in raising the stanchion, and

cushions the contact of the stanchion with the deck.

The counterbalancing spring (fig. 3-42) is a group

of three compression spring units (5) comprising five

3-40

14

12

9

13

13

14

12

1

13

13

4

7

11

6

2

5

8

3

10

1. PISTON

2. CYLINDER

3. FRONT CAP

4. REAR CAP

5. PISTON ROD

6. PLUNGER

7. HOSE

8. VENT VALVE ASSEMBLY

9. PLUG

10. PISTON ROD GLAND

11. PISTON GLAND

12. PACKING

13. 0-RING

14. SHIM

ABEf0341

Figure 3-41.—Hydraulic cylinder assembly.

1

2

3

4

6

7

5

1. EQUALIZING PLATE

2. CLEVIS

3. ROD

4. SPRING

5. COUNTERBALANCING SPRING UNIT

6. TERMINAL

7. CABLE

ABEf0342

Figure 3-42.—Counterbalancing spring assembly.