Newly constructed barricade webbing assemblies

may be brought out of storage and used as follows:

If used for three practice rigs, it can still be used

as a "ready" barricade for engagements.

If used for four or more practice rigs, it cannot be

used as a "ready" barricade.

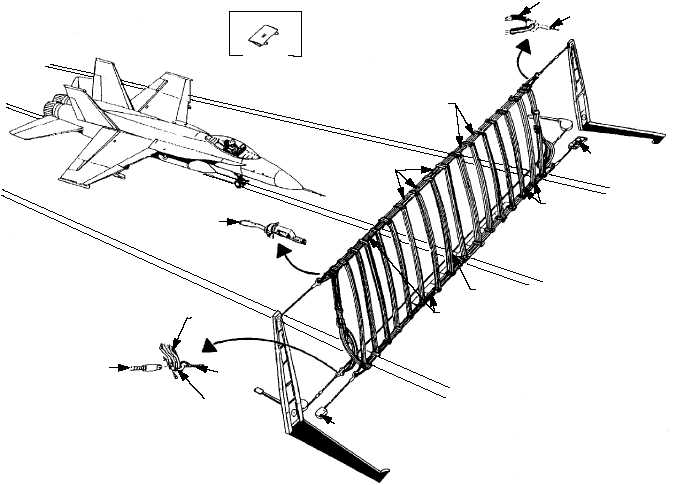

When an aircraft is required to make an emergency

landing, the nose of the aircraft passes through the

barricade and allows the vertical (engaging) straps to

contact the leading edges of the wings and wrap about

the aircraft (fig. 3-37). The barricade installation then

passes the force of arrestment through the purchase

cable to the arresting engine. After arrestment, the

barricade and attached hardware are discarded.

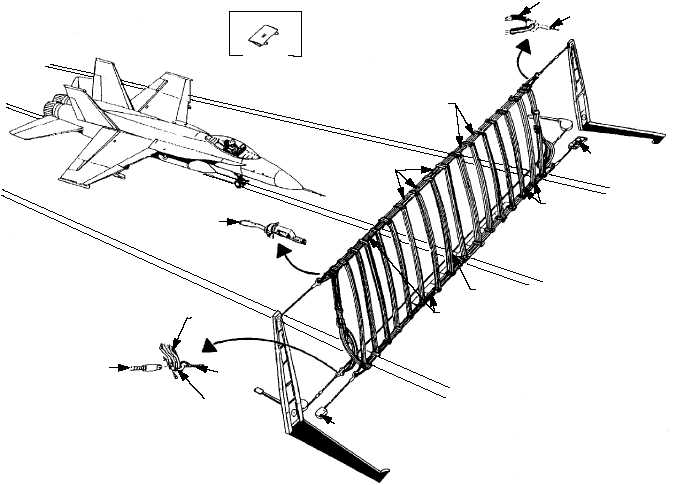

Currently, there are two types of barricades (two

configurations) available to the fleet. Both types consist

of all-nylon webbing assemblies, placed one on top of

the other and bundled together to make up one

barricade installation (see fig. 3-36).

The polyurethane semicoated barricade uses three

separate webbing systems to make one main webbing

assembly

Each semicoated barricade webbing system is

composed of upper and lower horizontal load straps

(see fig. 3-36) joined together at the ends by nylon

velcro tie-down straps. (The rolled edges of the upper

and lower load straps are coated with polyurethane to

reduce wear and damage caused when the barricade is

dragged into position for use.)

Vertical engaging straps, are looped around the

upper and lower load strap of each webbing system and

sewn.. The spacing between the vertical engaging

straps affords equalized loading of the barricade during

arrestment. One webbing assembly, effects equalized

loading every 4 feet along the wing's leading edge

3-36

ABE3f0337

RELEASE STRAPS

VELCRO TIE-DOWN

STRAPS

THREE WEBBING

ASSEMBLIES

ANCHOR

ASSEMBLY

ENGAGING STRAPS

REFER TO VIEW A

LOAD STRAPS

EXTENSION

LOOPS

EXTENSION

PENDANT

U-SHACKLE

PARALLEL

PENDANT

WINCH

DECK RAMP

VIEW A

BOOT

PELICAN HOOK

ASSEMBLY

Figure 3-37.—Emergency arrestment.