METERING PUMPS

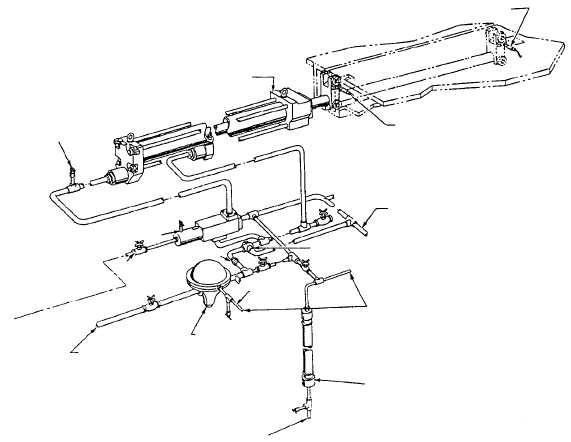

The metering pumps distribute lubricating oil to the

lubricator housing located on the cylinder covers. Each

metering pump contains a piston that separates the

metering pump into two chambers, a high-pressure

hydraulic chamber and a lube oil chamber.

LUBE OIL SYSTEM OPERATIONS

With the lube air solenoid deenergized, ac-

cumulator pressure supplied to the lube control valve,

acting on the differential area on the control valve

piston will keep the control valve shifted to the air

chamber side of the control valve. This allows the

high-pressure hydraulic side of the metering pumps

(fig. 4-36) to be vented through the control valve to the

gravity tank. With the lube pump running, the metering

pumps will fill with lube oil. When all metering pumps

are full, the lube oil pump discharge pressure will

increase to the pump relief valve setting (150-165).

Pump discharge will now recirculate to the stowage

tank while maintaining relief valve setting pressure

throughout the lube oil side of the system.

When the lube air solenoid is energized, it directs

low pressure air to the air chamber of the lube control

valve, overcoming the unbalanced control valve piston.

Low pressure air shifts the control valve allowing

accumulator hydraulic pressure to be directed to the

high-pressure hydraulic side of all the metering pumps

(see fig. 4-36). The lube oil in the metering pumps is

forced out through a relief valve and to the two injectors

in each of the cylinder covers. One lube injector directs

lube oil through the open cylinder slot and the other

injector is angled to direct lube oil onto the sealing

strip.

BRIDLE TENSIONING SYSTEM

LEARNING OBJECTIVES: Describe the

components of the bridle tensioning system.

Describe the function of the bridle tensioning

system.

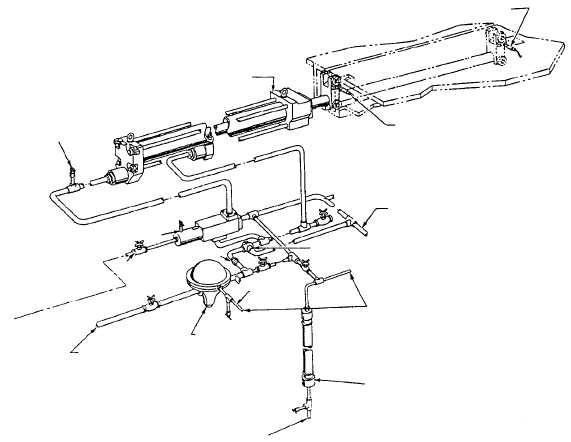

The bridle tensioning system (fig. 4-37) provides a

means of tightly connecting the aircraft to the shuttle

prior to firing the catapult. The bridle tensioning system

is comprised of components that directly apply a

forward force to the shuttle (external tension) and other

4-29

VENT VALVE

BRIDLE TENSIONER CYLINDER

BRIDLE TENSIONER FULLY-

EXTENDED LIMIT SWITCH

BRIDLE TENSIONER FULL-AFT

LIMIT SWITCH

HYDRAULIC FLUID LINE

(RETURN TO GRAVITY TANK)

RELIEF VALVE

AIR LINE

PRESSURE

REGULATOR

BRIDLE TENSIONER SURGE

ACCUMULATOR

TO TENSIONER-

ACCUMULATOR

AIR-CHARGING

VALVE AT

CHARGING PANEL

FROM MAIN

HYDRAULIC

ACCUMULATOR

FLUID SUPPLY

SHUTOFF

VALVE

ORIFICE

BRIDLE TENSIONER CONTROL

VALVE

TO TENSIONER-ACCUMULATOR-

HYDRAULIC AND DOME-AIR

PRESSURE DUPLEX GAUGE

AT CHARGING PANEL

ABEf0438

Figure 4-37.—Bridle tensioning system.