components that cause the retraction engine motor to

slowly rotate (internal tension). The components of the

external tensioning system is comprised of a bridle

tensioner pilot valve, a pressure regulator, a tensioner

control valve, a tensioner cylinder, a relief valve, and a

full aft limit switch.

NOTE

The Mk 2 nose gear launch unit is an integral

part of the bridle tensioning system. Its

description and operation is discussed later in

this manual.

TENSIONER PILOT VALVE

The tensioner pilot valve is located on the

retraction engine manifold and is used to actuate the

bridle tensioner control valve, internal tensioning inlet,

and outlet valve.

PRESSURE REGULATOR

The pressure regulator is used to reduce ac-

cumulator pressure to the pressure required for the

proper application (4000 plus or minus 250-ft lbs.)

through the grab to the shuttle. Reduced pressure from

the regulator is directed to the bridle tensioner control

valve and to the forward end of the bridle tensioner

cylinder.

BRIDLE TENSIONER CONTROL VALVE

The

tensioner

control

valve

directs

reduced

hydraulic pressure from the pressure regulator to the aft

end of the tensioner cylinder during the bridle tension

phase. At other times the control valve provides a vent

to the gravity tank for the aft end of the tensioner

cylinder.

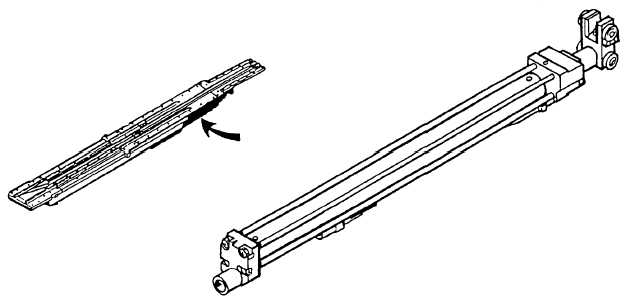

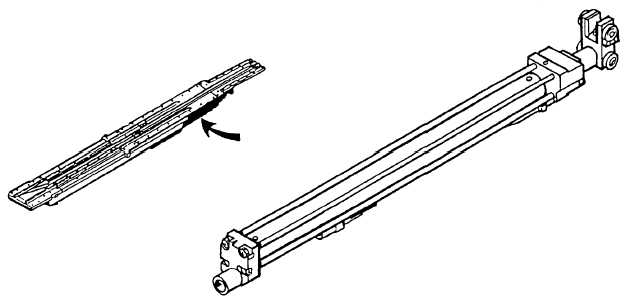

BRIDLE TENSIONER CYLINDER

The purpose of the tensioner cylinder is to exert

force on the catapult shuttle, via the shuttle grab

assembly, to tension the aircraft launching hardware

prior to launching. The bridle tensioner cylinder (fig.

4-38) is mounted directly below the nose gear launch

(NGL) track and in line with the aft trough covers. The

cylinder contains a piston with a rod extending out of

the forward end of the cylinder. The end of the rod is

fitted with a crosshead containing rollers, which

supports and aligns the piston rod within the track

formed by the two trough covers. A cam on the

crosshead is used to actuate the bridle tensioner full aft

limit switch.

RELIEF VALVE

The external tensioning relief valve is set to relieve

at 150 psi over the normally required pressure.

BRIDLE TENSIONER FULL AFT LIMIT

SWITCH

The full aft limit switch in the bridle tensioning

system is located in the aftermost trough cover, and are

actuated by a cam on the bridle tensioner piston rod

crosshead. The fully aft limit switch, when actuated,

allows completion of the RETRACT PERMISSIVE

circuit. This prevents retraction of the grab and shuttle

4-30

ABEf0439

Figure 4-38.—Tensioner cylinder assembly.