The bearing cups are shrink-fitted into the hub of

the wheel casting; the bearing cups are the parts on

which the bearings ride. The bearings are tapered roller

bearings. Each bearing is made of a cone and rollers.

This type of bearing absorbs side thrust as well as radial

loads and landing shocks. These bearings must be

cleaned and lubricated in accordance with the NAVAIR

04-10-1 manual.

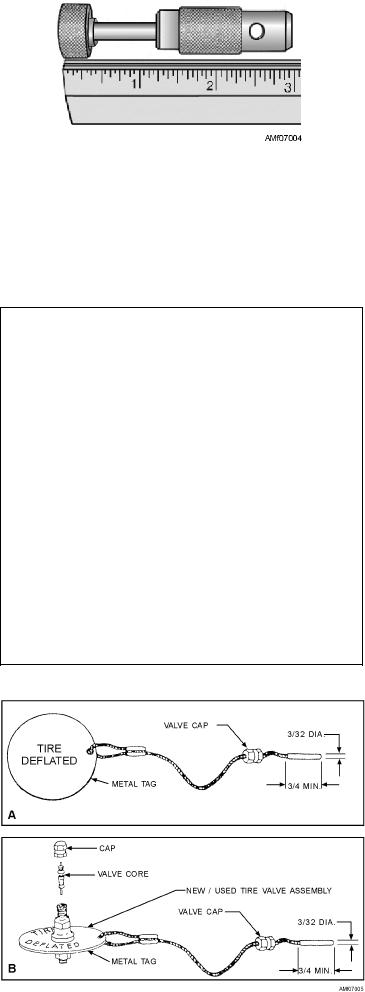

Figure 7-4.--Safe-core valve tool.

A three-piece grease retainer keeps the grease in

area. All wheel bearings should be lubricated at every

the inboard bearing and keeps out dirt and moisture.

tire change, and as required by the applicable

The retainer is composed of a felt seal and inner and

maintenance requirements cards (MRCs). All wheel

outer closure rings. A lockring secures the assembly

and bearing assemblies should be removed according to

inside the wheel hub.

the applicable maintenance instruction manual (MIM)

for that specific aircraft.

The hubcap seals the outboard side of the hub. It is

secured with a lockring. On some aircraft, the hubcap is

secured with screws.

WARNING

All wheels designed to be used on the main landing

gear are equipped with braking components. These

When a wheel is to be removed from an aircraft,

components are attached to the wheel casting. They

the nitrogen or dry air must be removed from the tire

may consist of either a brake drum or brake drive keys.

prior to removing the wheel. This should be done

The wheel shown in figure 7-3 is equipped with drive

with the Palmer Safe-Core valve tool (P/N 968RB),

keys. This wheel is designed for disc brakes.

which traps the valve core in the body of the Palmer

Safe-Core valve tool. See figure 7-4. This precaution

The trend in the military is toward smaller, faster,

must be taken because of the possibility that the bolts

more powerful aircraft with increased load carrying

in split wheels might have been sheared and cause the

capabilities. This means heavier loads and higher

wheel halves to separate when the axle nut is

landing speeds. The friction of long landing rollouts

removed. A tire deflated (valve core removed) metal

and taxiing causes heat to be absorbed by the wheel.

tag should be installed on the valve stem prior to

Because of the heat, possible wheel failure may occur.

removing the wheel from the axle. See figure 7-5.

This may damage equipment and injure personnel. To

Several people have been killed because they failed to

prevent this situation, aircraft manufacturers have

remove the air from the tire before removing the axle

developed a safety device called a "fusible plug." The

nut.

fusible plug contains an alloy that will melt and permit

the tire to deflate. This action occurs in the event the

wheel is exposed to excessive heat. Wheels that contain

fusible plugs should have a metal tag affixed that reads

"Fusible Plugs Installed."

ORGANIZATIONAL-LEVEL TIRE AND

WHEEL MAINTENANCE

Corrosion and loss of bearing lubrication are two of

the major causes of failure or rejection of aircraft

wheels. It is extremely important that all organizational

maintenance activities take precautions to protect

aircraft wheels/bearings from water, particularly salt

water. Wheel bearing lubrication gets contaminated

and/or breaks down, from excessive heat and water,

more often than it is lost. When wheels are exposed to a

stream of water (such as a hose), it will usually

penetrate the hub area, contaminating the bearing

Figure 7-5.--(A) Deflated tire flag, (B) Storage of valve core

lubricant. This contributes to corrosion in the bearing

and cap using alternate deflated tire flag.

7-3