Painting

6. Thoroughly dry the wheel with compressed air.

7. Immerse the wheel portion in solution B, and

When the wheel paint has deteriorated to the extent

allow it to soak for 20 minutes.

that touch-up is not feasible, wheels may be stripped

and repainted. Stripping and repainting are allowed

8. Place the wheel portion on a grill over solution

only if the IMA is authorized to paint with aliphatic

B, and spray it thoroughly with solution B. Remove any

polyurethane.

remaining soil or grease deposits with liberal amounts

of solution B and bristle brushes.

Cleaning

9. Thoroughly wash the wheel portion with a

high-pressure stream of clean water to remove all

To inspect aircraft wheels for cracks, physical

solvents. Compressed air may be used to dry the wheel.

damage, and corrosion, they must be clean. All dirt,

rubber, and grease deposits must be completely

Inspection

removed. Cleaning for appearance sake is not a

requirement. Removing stains is not a necessity. Many

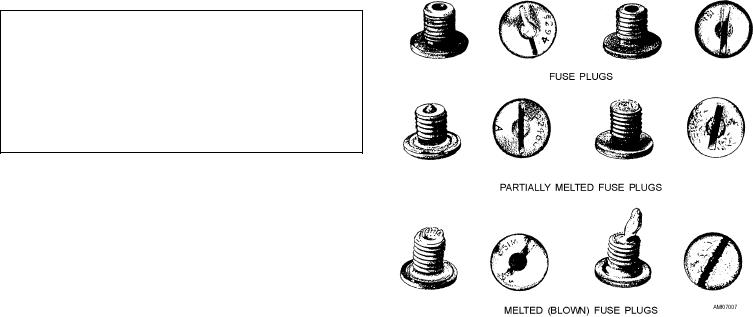

You should perform a visual inspection of the

wheels will be discolored after the rubber deposits have

wheel for cracks, loose bearing cups, corrosion,

been removed from the tire bead areas. This

physical damage, and melted fusible plugs. See figure

discoloration is acceptable, and further cleaning is not

7-7. Forward all wheels with cracks or loose bearing

necessary. Discolored areas around brake keys are

cups to supply for overhaul. Partially melted fuse plugs

difficult to remove without damaging the paint.

should not cause a wheel to be rejected. The plug may

The following steps describe the wheel cleaning

not need to be replaced. If the eutectic core material

procedures. Further information regarding the cleaning

does not extend more than one-sixteenth of an inch

of aircraft wheels can be found in Aircraft Wheels,

above the top surface of the hex head, the plug may be

NAVAIR 04-10-1.

kept in service "as is" with no restrictions. If the

eutectic core material at the threaded end is not

Clean the wheels as follows:

depressed more than one-sixteenth of an inch and there

1. Prepare one tank (solution A) of cleaning

is no evidence of pinholes, the plug may be kept in

solution that consists of 4 to 9 parts cleaning solvent

service with no restrictions. Do not file, sand, or

(P-D-680) and 1 part solvent emulsion cleaner

remove the eutectic material. If the eutectic material

(P-C-444).

appears to be filed, sanded, or broken, you should

assume the serviceable limits have been exceeded and

2. Prepare another tank (solution B) of cleaning

reject the plug.

solution that consists of 4 to 9 parts of clean water and 1

part emulsion cleaner (MIL-C-43616).

WARNING

You should use P-D-680 solvent only in

well-ventilated areas. You should also avoid skin

contact by wearing protective equipment for your

eyes and hands.

3. Place the wheel portion to be cleaned on a grill

over solution A, and spray it thoroughly with solution A

to remove all loose grease and soil.

4. Immerse the wheel portion in solution A, and

allow it to soak for 20 minutes.

5. Repeat step 3, and then scrub the tire bead areas

with bristle brushes to remove the rubber deposits. Do

Figure 7-7.--Fuse plugs.

not use wire brushes.

7-6