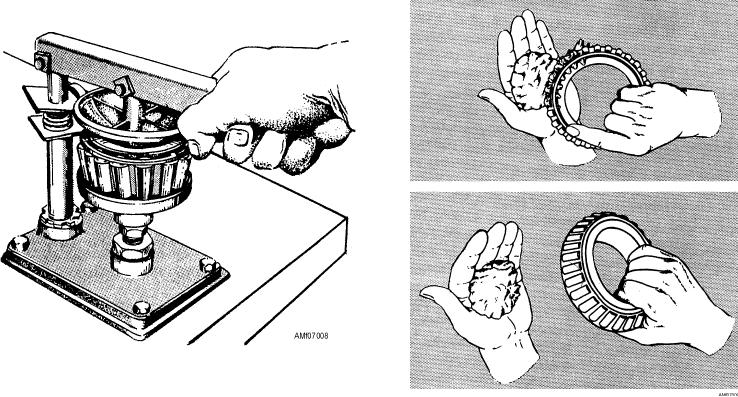

You should repack bearings with MIL-G-81322

You should perform the eddy current and dye

grease. Bearings may be repacked either with pressure

penetrant inspections for wheels listed in NAVAIR

equipment or by hand. See figures 7-8 and 7-9. The

04-10-1. Inspect all tie bolts for corrosion, elongation,

pressure method is recommended because it is easier,

bending, stripped threads, or deformed shanks. You

faster, and reduces the possibility of contamination.

should also perform a magnetic particle inspection for

The pressure method assures a more even distribution

cracks according to NAVAIR 01-1A-16. Any of the

of grease within the bearing.

listed defects is cause for rejection of the tie bolt.

Self-locking tie bolt nuts may be reused provided the

NOTE: You should ensure bearings are completely

nut cannot be turned onto the tie bolt by hand with the

dry before packing them with lubricant.

fingertight method prescribed in Structural Hardware,

You should also spread a thin layer of grease on the

NAVAIR 01-1A-8. On disc wheels, you should inspect

bearing cups. Inspect the grease retainers for evidence

brake keys or gears for wear and looseness in

of deterioration, contamination, or water saturation.

accordance with NA 04-10-1. Replace worn brake keys

You should replace them if necessary. Presoak the

and gears or reattach loose brake keys and gears in

retainers with VV-L-800 oil prior to installing them.

accordance with NA 04-10-1. Corrosion or rust on

brake keys and gears is common, and is not cause for

Refer to the NA 01-1A-503 manual for more

rejection.

detailed information on wheel bearing maintenance.

Bearing Maintenance

Corrosion and Physical Damage Blendout

You should remove and inspect the bearing cone

Limited and isolated corrosion and physical

and roller assemblies according to the applicable MIM.

damage should be blended. Wheel rims, outside ends of

Thoroughly clean the bearings, bearing cups, wheel

bearing hubs, nicks, gouges, and pock marks are not

bores, and grease retainers with P-D-680, type II,

considered significant unless the defect is deeper than

solvent to remove the grease, preservative compounds,

0.020 of an inch. The defect should not be blended out

and contamination.

unless there is active corrosion in the defect. However,

all burrs must be removed. Corrosion or other defects

NOTE: The organizational-level and inter-

should be blended out not to exceed a maximum of

mediate-level procedures for cleaning and inspecting

one-sixteenth of an inch. All damage must be removed

wheel bearings, retainers, cups, and cone and roller

within this allowance. The maximum depth of blendout

assemblies are the same.

for all other wheel areas is 0.010 of an inch.

Figure 7-8.--Pressure repacking of wheel bearings.

Figure 7-9.--Hand repacking of wheel bearings.

7-7