CHAPTER 11

BASIC ACTUATING SYSTEMS

INTRODUCTION

either single or double acting. Unlike the balanced

actuator, it has a single piston shaft extending from the

The actuating systems consist of the hydraulic

piston head, resulting in unequal working areas. Each

components used to direct and control the flow of

actuator used may differ considerably in size and

pressurized fluid as well as the components used to

construction.

perform the actual work. This chapter covers actuating

units and most of the various actuating system

Single-Acting Actuating Cylinder

components that are used in modern-day hydraulic

The single-acting, piston-type cylinder uses fluid

systems.

pressure to apply force in only one direction. In some

designs of this type, the force of gravity moves the

ACTUATING UNITS

piston in the opposite direction. However, most

cylinders of this type apply force in both directions.

LEARNING OBJECTIVE: Identify various

Fluid pressure provides the force in one direction, and

hydraulic actuating units.

spring tension provides the force in the opposite

direction. In some single-acting cylinders,

An actuating unit may be defined as a unit that

compressed air or nitrogen is used instead of a spring

transforms hydraulic fluid pressure into mechanical

for movement in the direction opposite that achieved

force, which performs work (moving some

with fluid pressure.

mechanism). Two types of actuating units are used in

naval aircraft--actuating cylinders and hydraulic

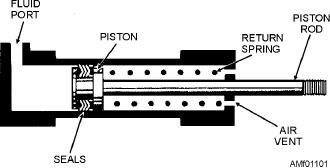

Figure 11-1 shows a single-acting, spring-loaded,

motors.

piston-type actuating cylinder. In this cylinder the

spring is located on the rod side of the piston. In some

TYPES OF ACTUATING CYLINDERS

spring-loaded cylinders, the spring is located on the

blank side, and the fluid port is located on the rod side

Actuating cylinders are the most commonly used

of the cylinder.

actuating units in aircraft hydraulic systems. The

A three-way directional control valve is normally

purpose of an actuating cylinder is to convert fluid

used to control the operation of this type of cylinder.

under pressure into linear or mechanical motion.

To extend the piston rod, fluid under pressure is

Actuating cylinders are generally installed in such a

directed through the port and into the cylinder. See

manner that the piston shaft (rod) end of the cylinder is

figure 11-1. This pressure acts on the surface area of

attached to the mechanism to be actuated, with the

the blank side of the piston, and forces the piston to the

other end attached to the aircraft structure.

right. This action, of course, extends the rod to the

There are two types of actuating cylinders--

right, through the end of the cylinder. The actuated unit

balanced or unbalanced. Balanced actuators have

is moved in one direction. During this action, the

equal working areas, with a piston shaft extending

from both sides of the piston head. This type of

cylinder may be a single-acting actuator, which

receives hydraulic pressure on only one side of the

piston head for movement in one direction, and some

other means of force for movement in the opposite

direction. However, it may also be a double-acting

type, which uses hydraulic pressure alternately on both

sides of the piston head to move it in the selected

direction.

The most common type of actuating cylinder used

Figure 11-1.--Single-acting, spring-loaded, piston-type,

on naval aircraft is the unbalanced type, which may be

actuating cylinder.

11-1