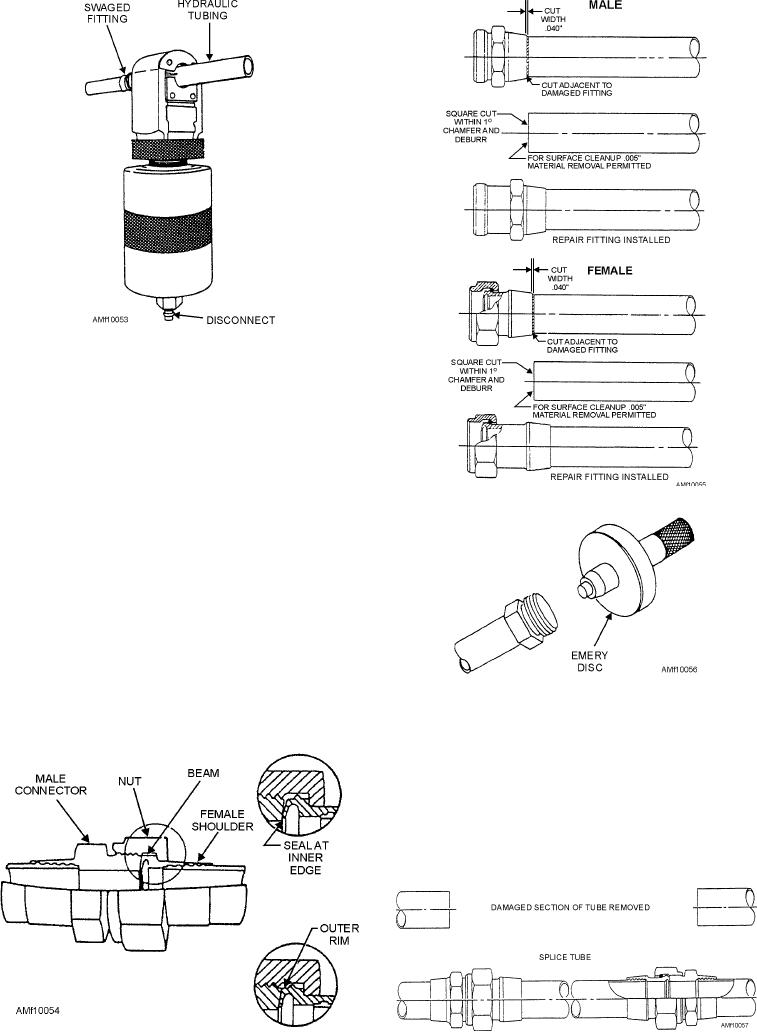

Figure 10-53.--Series D12200 kit swage tool operation.

As a supplement to the series D10000 tool kits, the

series D12200 tool kits (fig. 10-53) may be used. The

newer type of tooling is smaller in size and is designed

to repair tubing on board aircraft.

The portable hydraulic power supply D10004 (fig.

10-51) generates 5,500 psi to operate the swaging tool.

Hydraulic fluid is fed to the tool through a 1/4-inch

Figure 10-55.--Male and female repair fitting installation.

quick-disconnect, high-pressure hose. As a precaution

against premature tool fatigue, the swaging pressure is

kept from exceeding 5,500 psi by the pressure relief

valve. The D10004 hydraulic power supply can be

operated either manually by using a hand pump or

automatically by air-to-hydraulic fluid intensification

from a 80 20 psi pressure shop air source.

DYNATUBE FITTING REPAIR.--Dynatube

fittings consist of a threaded male connector, a female

Figure 10-56.--Dynatube fitting resurfacing tool.

shoulder with a machined beam, and a nut (fig. 10-54).

Compared to the five components in a standard MS

fitting, the three components in a Dynatube fitting are

smaller, lighter, and have fewer potential leak paths.

Dynatube fittings can be connected to rigid tubing by

welding, but internal mechanical swaging with

Resistoflex hand tools is the authorized method for

Navy personnel.

The repair methods using Dynatube fittings are

illustrated in figures 10-55 through 10-57.

Figure 10-54.--Dynatube fitting.

Figure 10-57.--Splice assembly repair.

10-47