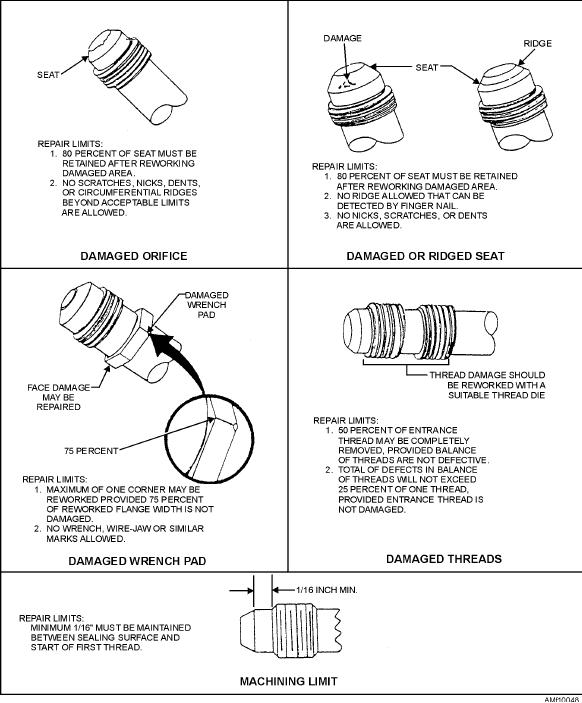

Some minor surface damages to tubing are

AN815 unions. Position the AN818 nuts and AN819

acceptable, as described in inspection of tubing

sleeves on the new section. A new section is not

damage. A nick that is not deeper than 15 percent of the

required when the length of the union is longer than the

wall thickness of aluminum, aluminum alloy, or

damaged section. Install the new section of tubing and

corrosion-resistant steel is acceptable after being

tighten the AN818 nuts. Permanent repairs include

reworked by burnishing with hand tools. Minor damage

removal of minor damage on tubing and fittings and the

to fittings is defined as damage not to exceed repairable

replacement of line sections or fittings by Permaswage

limits, as shown in figure 10-48.

or Dynatube swaging equipment, or by induction

brazing.

Fittings that exceed repairable limits should be

replaced. To repair damaged fittings, proceed as

NOTE: Induction brazing is limited to depot-level

follows: To repair damaged orifices, remove any

repair. Tube assemblies used for engine-related

restriction in the orifice and handstone it to blend rough

hydraulic, fuel, oil, vent or drain lines usually have

edges or burrs, as shown in view A of figure 10-48.

brazed or welded end fittings. These engine-related

To repair damaged or ridged seats, resurface

tube assemblies are normally fabricated from

circumferential ridges with annular tool, as shown in

corrosion-resistant steel.

Figure 10-48.--Reworking damaged fittings.

10-44