Storage

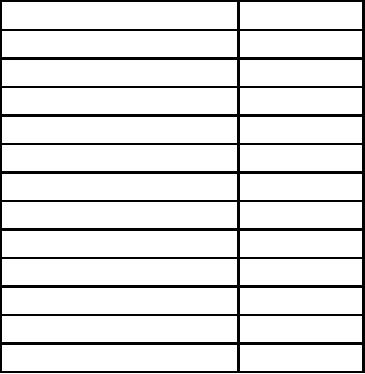

Table 10-16 lists some of the fluids with which you

may be required to work and the hazards associated

Fabricated tubing and tube assemblies requiring

with each one.

storage for any length of time should be provided with

protective closures at each end.

Table 10-16.--Hazards Associated with Various Fluids

Do not use pressure-sensitive tape as a substitute

for protective closures. Oxygen tube assemblies require

Contents

Hazard

protection of the entire assembly in addition to

Air (under pressure)

PHDAN

protective closures at end fittings. The complete

assembly should be stored and packaged in sealed

Alcohol

FLAM

plastic bags in accordance with Aviation Crew Systems

Carbon dioxide

PHDAN

Manual Oxygen Equipment, NA 13-1-6.4.

Freon

PHDAN

TUBING AND TUBE ASSEMBLIES

Gaseous oxygen

PHDAN

MAINTENANCE PROCEDURES

Liquid nitrogen

PHDAN

Maintenance of tube assemblies at the

Liquid oxygen

PHDAN

organizational level is limited to inspection, removal,

installation, repair and replacement. Inspections are

LPG (liquid petroleum gas)

FLAM

performed during fabrication, installation, and on

Nitrogen gas

PHDAN

in-service equipment. During fabrication, inspect bulk

tubing and fittings before and during fabrication of a

Oils and greases

FLAM

tube assembly. Before replacing a defective tube

JP-5

FLAM

assembly, find the cause of failure, and inspect the tube

assembly before and after its installation. Inspect

Trichloroethylene

AAHM

in-service tube assemblies at regular intervals in

accordance with applicable maintenance directives.

For convenience in distinguishing one hydraulic

When you inspect the tube and tube assemblies for

line from another, each line is designated as to its

damage, look for chafing, galling, or fretting, which

function within the system. In general, the various

may reduce the ability of tubing to withstand internal

hydraulic lines are designated as follows:

pressure and vibration. Replace tubing that shows

Supply lines. Lines that carry fluid from the

visible penetration of the tube wall surface caused by

reservoir to the pumps are called supply (or suction)

chafing, galling, or fretting. Tubes that have damage

lines.

(nicks, scratches, or dents) caused by careless handling

of tools are acceptable if they meet the following

Pressure lines. Lines that carry only pressure are

requirements: Any dent that has a depth less than 20

called pressure lines. Pressure lines lead from the

percent of the tubing diameter is acceptable unless the

pumps to a pressure manifold, and from the pressure

dent is on the heel of a short bend radius. A nick or

manifold to the various selector valves, or they may run

scratch that has a depth of less than 15 percent of the

directly from the pump to the selector valve.

wall thickness of aluminum, aluminum alloy, or steel

Operating lines. Lines that alternately carry

tubing should be reworked by burnishing with hand

pressure to an actuating unit and return fluid from the

tools before it is acceptable. Any aluminum, aluminum

actuating unit are called operating lines, or working

alloy, or steel tubing carrying pressures greater than

lines. Each operating line is identified in the aircraft

100 psi with nicks or scratches greater than 15 percent

according to its specific function; for example,

of wall thickness should be replaced.

LANDING GEAR UP, LANDING GEAR DOWN,

Inspect each fitting (fig. 10-44) before it is

FLAPS UP, FLAPS DOWN.

installed. Visually or flow check to make sure that

fitting passage or passages are free from obstructions.

Return lines. Lines that are used to return fluid

from any portion of the system to the reservoir are

Installation

called return lines.

Installation of tube assemblies involves a pre-

Vent lines. Lines that carry excess fluid overboard

installation check before tube assemblies can be

or into another receptacle are called vent lines.

10-40