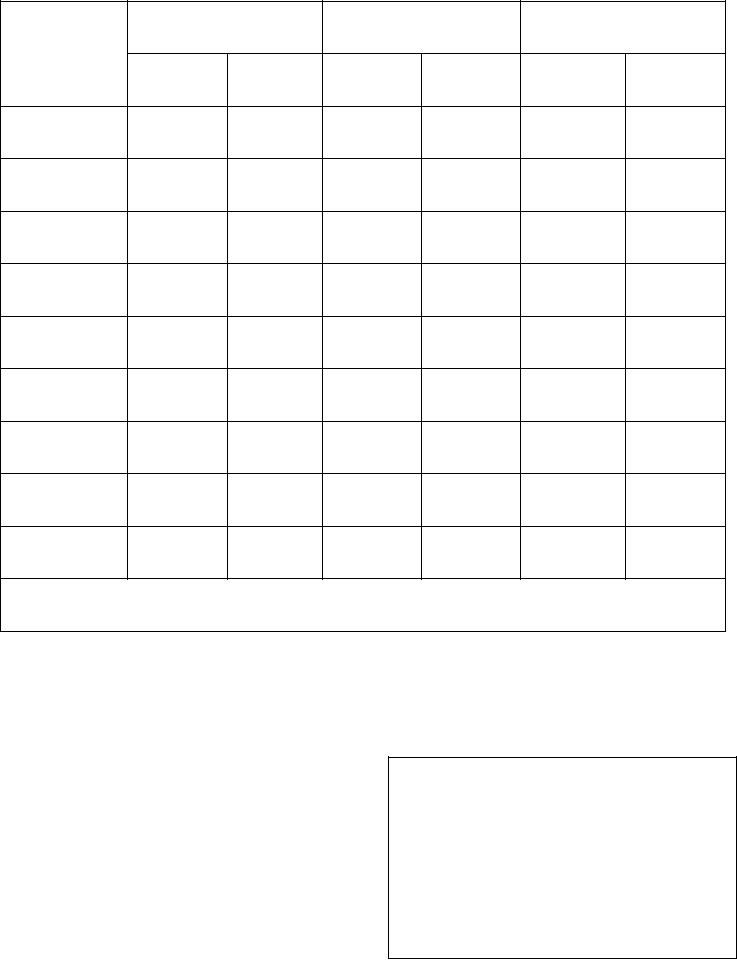

Table 10-14.--Minimum Inside Diameter of Tubing

TUBE

6061 ALUMINUM

1/8 HARD STAINLESS

ANNEALED STAINLESS

OUTSIDE

DIAMETER

WALL

MIN ID

WALL

MIN ID

WALL

MIN ID

1/8

0.020

0.060

0.016

0.070

0.020

0.060

3/16

0.028

0.095

0.018

0.110

0.020

0.115

1/4

0.035

0.150

0.020

0.165

0.028

0.155

5/16

0.049

0.180

0.022

0.225

0.035

0.225

3/8

0.049

0.240

0.025

0.290

0.049

0.270

1/2

0.065

0.330

0.028

0.400

0.058

0.380

5/8

0.083

0.420

0.035

0.485

0.065

0.475

3/4

0.095

0.530

0.042

0.610

0.083

0.590

1

0.065

0.830

0.065

0.840

0.083

0.800

All measurements are in inches.

temperature specified in the manufacturing instruc-

Oxygen tubing should be tested using dry nitrogen and

tions is reached. Tube assemblies must be blown

inspected for leaks while the tubing is submerged in

clean and dried with a stream of clean, dry,

water.

water-pumped air.

Cleaning Tubing and Tube Assemblies

All tubing and tube assemblies must be cleaned

CAUTION

after fabrication to prevent contamination of the system

Oil-pumped air is not a suitable substitute

in which they will be installed. Dry-cleaning solvent

for water-pumped air because it causes oil to be

MIL-PRF-680, Type II, is the preferred cleaner.

deposited in the tube assemblies. Oxygen reacts

Oxygen system tube assemblies require special

violently with oil and may cause equipment dam-

precautions for cleaning. After fabrication, and testing,

age and injury to personnel. Oxygen (BB-O-925)

clean oxygen tube assemblies in accordance with

or clean, dry, water-pumped nitrogen (BB-N-411)

MIL-STD-1330D. If a vapor degreaser is not used, tube

must be used in place of water-pumped air.

assemblies must remain in the vapor degreaser until the

10-35