sure that all tube material and tools are kept free of oil

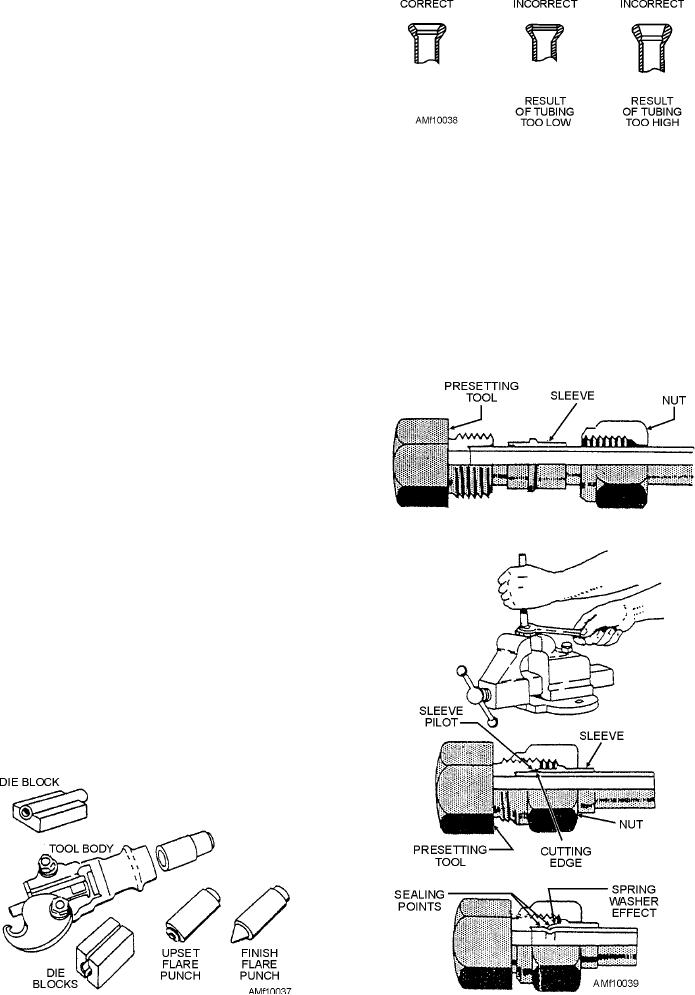

and grease. Use the tube flaring tool (fig. 10-37) to

prepare tube ends. Check tube end for roundness,

square cut, cleanliness, and make sure there are no draw

marks or scratches. Draw marks can split the tubing

when it is flared.

Use a deburring tool to remove burrs from the

Figure 10-38.--Tube position and resulting flare.

inside and outside of tube. Remove filings, chips, and

grit from inside the tube. Clean the tube. Select the

always be accomplished with a presetting tool, such as

proper size die blocks, and place one-half of the die

the one shown in figure 10-39. These tools are

block into the flaring tool body with the countersunk

machined from tool steel and hardened so that they may

end towards the ram guide. Install the nut and sleeve,

be used with a minimum of distortion and wear.

and lay the tube in the die block with 1/2 inch

NOTE: A flareless-tube connector may be used as

protruding beyond countersunk end. Place the other

a presetting tool in case of an emergency. However,

half of the die block into the tool body, close latch plate,

when connectors are used as presetting tools, aluminum

and tighten the clamp nuts fingertight. Insert the upset

connectors should be used only once, and steel

flare punch in the tool body with the gauge end toward

connectors should not be used more than five times.

the die blocks. The upset flare punch has one end

counterbored or recessed to gauge the amount of tubing

needed to form a double lap flare. Insert the ram and tap

lightly with a hammer or mallet until the upset flare

punch contacts the die blocks, and the die blocks are set

against the stop plate on the bottom. Use a wrench to

tighten the latch plate nuts alternately, beginning with

the closed side, to prevent distortion of the tool.

Reverse the upset flare punch; insert the upset flare

punch and ram into the tool body. Tap lightly with a

hammer or mallet until the upset flare punch contacts

the die blocks. Remove the upset flare punch and ram.

Insert the finishing flare punch and ram. Tap the ram

lightly until a good seat is formed (fig. 10-38). Check

the seat at intervals during the finishing operation to

avoid overseating.

FLARELESS FITTINGS.--Preparing tube ends

for flareless fitting requires a presetting operation

whereby the sleeve is set onto the tubing. Presetting is

necessary to form the seal between the sleeve and the

tube without damaging the connector. Presetting should

Figure 10-39.--Presetting flareless-tube assembly.

Figure 10-37.--Tube flaring tool (double-flare).

10-33