Special procedures are used in the presetting

operation. Select the correct size presetting tool or a

flareless fitting body. Clamp the presetting tool or

flareless fitting body in a vise. Slide a nut and then a

sleeve onto the tube, and make sure the pilot and cutting

edge of the sleeve points toward the end of tube. Select

the lubricant from table 10-12, and lubricate fitting

threads, tool seat, and shoulder sleeve. Place the tube

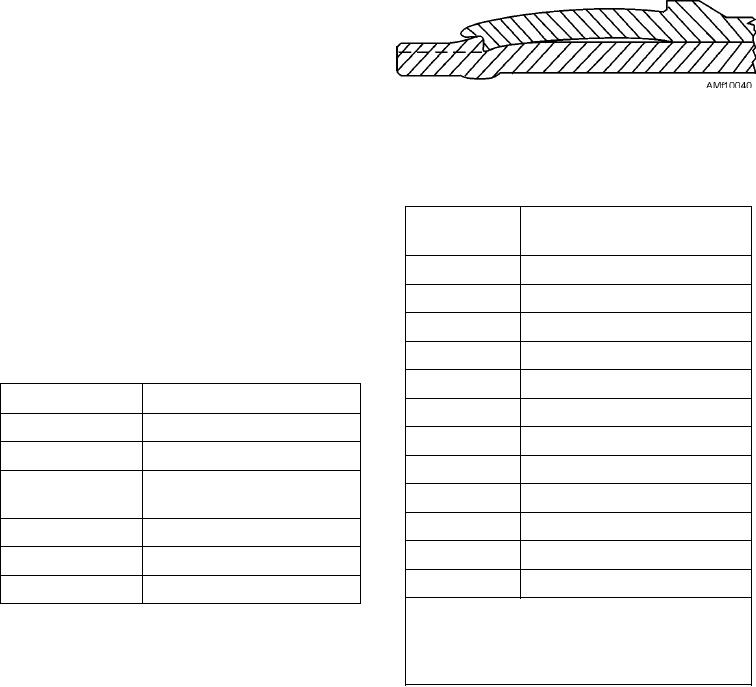

Figure 10-40.--Preset sleeve.

end firmly against the bottom of the presetting tool seat,

while slowly screwing the nut onto the tool threads with

Table 10-13.--Tube Projection from Sleeve Pilot

a wrench until the tube cannot be rotated with thumb

and fingers. At this point the cutting edge of the sleeve

TUBE SIZE

*APPROXIMATE TUBE

is gripping the tube and preventing tube rotation; the

PROJECTION-INCHES

fitting is ready for the final tightening force needed to

set the sleeve on the tube. Tighten the nut to the number

2

7/64

of turns specified in Aviation Hose and Tube Manual,

3

7/64

NAVAIR 01-1A-20.

4

7/64

5

5/32

Table 10-12.--Thread Lubricants

6

11/64

SYSTEM

LUBRICANT

8

3/16

Hydraulic

Specification MIL-H-5606

10

13/64

Fuel

Specification MIL-H-5606

12

7/32

Oil

Specification MIL-O-6032 or

16

15/64

MIL-L-23699

20

1/4

Freon

Specification MIL-L-6085A

24

1/4

Pneumatic

Specification MIL-G-4343

32

9/32

Oxygen

Specification MIL-T-27730A

*The figures vary upon change of wall thickness

for a given size. Do not use these dimensions

After presetting, unscrew the nut from the

as an inspection standard, but rather as an

presetting tool or flareless fitting body; check the sleeve

approximation of proper tube projection.

and tube (fig. 10-40). Sleeve cutting lip should be

imbedded into the tube's outside diameter between

0.003 inch and 0.008 inch, depending on size and

Proof Pressure Testing

tubing material. A lip of tube material will be raised

under the sleeve pilot. The sleeve pilot should contact

Tube assemblies that are fabricated according to

or be quite close to the outside diameter of tube. The

the instructions in Aviation Hose and Tube Manual,

tube projection from the sleeve pilot to the tube end

NAVAIR 01-1A-20, should be proof pressure tested to

should be as listed in table 10-13. The sleeve should be

twice the operating pressure of the system in which

bowed slightly. The sleeve may rotate on tube and have

they are to be installed, provided the operating pressure

a maximum lengthwise movement of 1/64 inch. The

is greater than 50 psi. Tubing, installed in systems

sealing surface of the sleeve, which contacts the

having an operating pressure of less than 50 psi must be

24-degree angle of fitting body seat, should be smooth,

proof pressure tested to a minimum of 100 psi. Vent

free from scores, and should not show lengthwise or

tubes or drain tubes do not require proof pressure

circular cracks. Crazing cracks in finish are not harmful

testing.

to safety or function of fitting. Minimum internal tube

The fluid medium for proof pressure testing of all

diameter should not be less than values shown in table

tube assemblies except oxygen systems should be a

10-14.

liquid medium such as hydraulic fluid, water, or oil.

10-34