its open side (fig. 10-29). As the cutter is rotated, adjust

the tightening knob after each complete turn to

maintain light pressure on the cutting wheel.

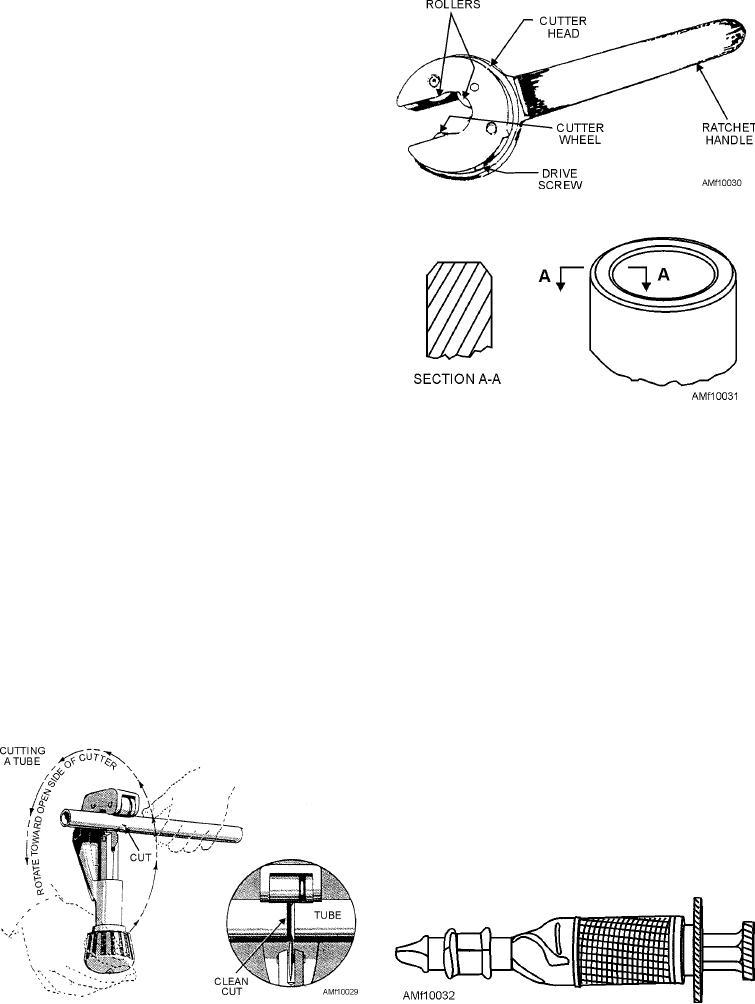

PERMASWAGE CHIPLESS CUTTER.--

Select the chipless cutter according to tubing size.

Rotate cutter head to accept tubing in cutting position.

Check to ensure the cutter ratchet is operating freely

and the cutter wheel is clear of the cutter head opening

(fig. 10-30).

Center the tubing on two rollers and cutting blade.

Use the hex key provided with the kit to turn the drive

Figure 10-30.--Permaswage chipless cutter.

screw in until the cutter wheel touches the tube. Tighten

the drive screw one-eighth to one-fourth turn. Do not

overtighten the drive screw. Overtightening can

damage soft tubing or cause excessive wear or breakage

of the cutter wheel in hard tubing. Swing ratchet handle

back and forth through the available clearance until

there is a noticeable ease of rotation. Avoid side force

on cutter handle. Side force will cause the cutter wheel

to break. Tighten the drive screw an additional

one-eighth to one-fourth turn, and swing ratchet handle

back and forth, retightening drive screw as needed until

Figure 10-31.--Properly deburred tubing.

cut is completed.

If neither tube cutter (standard or Permaswage) is

may be used to remove burrs from inside of tubing.

available, a fine-tooth hacksaw should be used to cut

Select deburring tool and stem subassembly (fig.

tubing. A convenient method for cutting tubing with a

10-32) required for the size of tubing to be deburred.

hacksaw is to place the tube in a flaring block and the

Lubricate the sliding collar on the end of elastic plug

clamp block in a vise. After cutting the tube with a

with light oil if necessary to get free movement. Engage

hacksaw, remove all saw marks by filing the tube.

threads and insert stem subassembly into cutter end of

deburring tool by depressing the plunger, and screw

Tube Deburring

stem subassembly into plunger until it bottoms and

fingertightens. Check assembly deburring tool.

After you cut the tubing, remove all burrs and sharp

Depress plunger and the plug. Outside diameter should

edges from inside and outside of tube (fig. 10-31) with

be reduced to the same diameter as metal support collar

deburring tools. Clean out tubing. Make sure that no

on either end of elastic plug. Release plunger. Two

foreign particles remain. A Permaswage deburring tool

distinct circumferential bumps will appear on elastic

plug beyond outside diameter of metal support collars.

Check the tube end for squareness. Check the elastic

plug for wear and cleanliness. Replace worn or

damaged elastic plug. Clean and lightly lubricate

elastic plug with lubricant compatible to hydraulic fluid

to be used in tubing. Grasp deburring tool in one hand

with two fingers on collar and thumb on plunger.

Depress plunger with thumb and insert elastic plug into

Figure 10-32.--Permaswage deburring foot (typical).

Figure 10-29.--Standard tube cutter.

10-30