If an aluminum alloy flared tube assembly leaks

installed. Before you install tube assemblies, check to

after it has been tightened to the required torque,

make sure there are no dents, nicks, and scratches; that

disassemble it for repair or replacement. If a steel flared

the assembly contains the correct nuts and sleeves; that

tube assembly leaks, it may be tightened one-sixteenth

there is a proper fit, where fitting is flared; that a proof

turn beyond the noted torque. If the assembly continues

pressure test is performed on each assembly; and that

to leak, it should be disassembled for repair or

the assemblies are clean.

replacement. Do not tighten a nut when there is

To install tube assemblies, hand screw the nuts onto

pressure in the line. Do not overtighten a leaking

mating connectors. Align the tube assembly in place so

aluminum alloy assembly. Overtightening may

that it will not be necessary to pull it into place with the

severely damage or cut off tubing flare, or damage

nut. Tubing that runs through cutouts should be

sleeve or nut.

installed to avoid scarring when the tubing is worked

When you install flareless tube assemblies,

through a hole. If the tube assembly is long, tape the

proceed as follows: Make sure no nicks or scratches are

edge of cutouts before installing the assembly. Torque

evident and the sleeve is preset. Tighten the nut by hand

the nuts. Apply a protective coating to the remaining

until resistance to turning develops. If it is impossible to

nonsealed joints after tubing is installed. For

use fingers to run nut down, use a wrench. Look out for

disconnected nonsealed joints, apply MIL-S-8802,

the first signs of bottoming. Do not use pliers to tighten

followed by appropriate paint system, if required. For

tube connectors.

connected nonsealed joints, apply the first coat of

MIL-C-16173, grade 4; 1 hour after applying the first

Final tightening should begin at the point where the

coat, apply the second coat of MIL-C-16173, grade 4.

nut begins to bottom. Use a torque wrench if fitting is

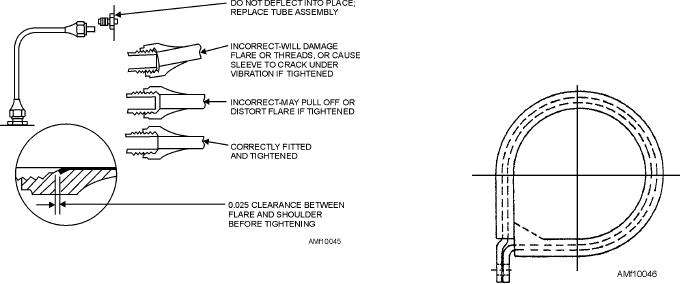

Correct and incorrect methods of installing flared tube

accessible and torque fitting. If a connection is not

assemblies are shown in figure 10-45.

accessible for torque wrench, use a wrench to turn nut

one-sixth turn while holding the connector with another

Leakage of a flared tube assembly is usually caused

wrench to prevent the connector from turning. A

by the following:

one-sixth turn equals the travel of one flat on a hex nut.

Flare distorted into the nut threads.

Tighten nut an additional one-sixth turn if the connector

Sleeve cracked.

leaks. Do not tighten fitting nut more than one-third of a

turn (two flats on nuts). Loosen and completely

Flare out of round.

disconnect the nut if the leak continues. Inspect fitting

components for scores, cracks, foreign material, or

Flare cracked or split.

damage from previous overtightening. Reassemble

Inside of flare rough or scratched.

fitting. Fingertighten nut and repeat wrench tightening.

It is important to tighten tube fitting nuts properly. A

Connector mating surface rough or scratched.

fitting wrench or an open-end wrench should be used

Connector threads or nuts are dirty, damaged, or

when tightening connections.

broken.

All hydraulic tubing should be supported from

rigid structures by cushioned steel clamps

MIL-C-85052 or multiple tube block clamps. See

figure 10-46. Hydraulic tubing support clamps should

be installed and maintained in the positions described

in the MIM or applicable technical directives.

Figure 10-45.--Correct and incorrect methods of installing

flared fittings.

Figure 10-46.--Cushioned steel clamps MIL-C-85052.

10-42