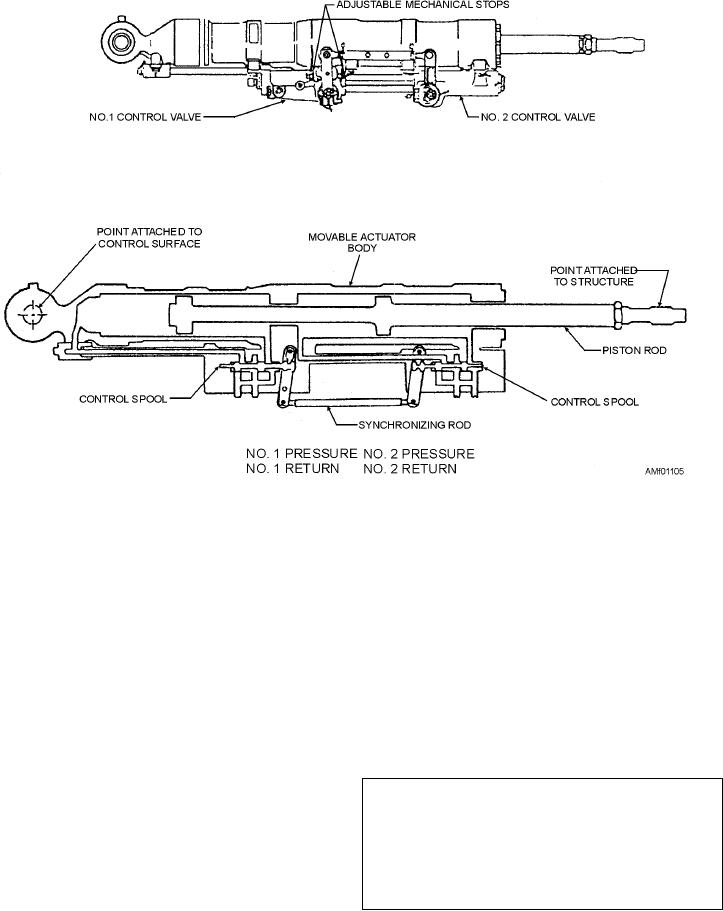

Figure 11-5.--Control surface actuating cylinder.

two end cap assemblies, the two control valves, and the

NOTE: All lubrication fittings and lubrication

previously mentioned synchronizing rod.

areas must be cleaned prior to lubrication, and all

excess lubricants must be removed at its completion.

In this particular installation, the piston shaft end is

attached to the aircraft structure and remains

External leakage is the most common trouble

stationary. The cylinder body is attached to the control

encountered with actuating cylinders. Static or

surface, and provides control surface deflection by its

dynamic seals can cause this. Static seal leakage

movement. Two adjustable stops are provided as a

around end caps or fittings may be stopped by

means of adjusting actuator movement, thereby

tightening the affected components or replacing the

limiting the travel of the control surface. When these

leaking seal. Dynamic seal leakage around an actuator

steps are used in an aileron or elevator control system,

shaft will require seal replacement. Refer to the

one stop limits the UP travel, and the other limits the

appropriate maintenance instructional manual (MIM)

DOWN travel. In a rudder system, one stop limits the

or 03 Manual for specific maintenance instructions.

travel to the right, and the other to the left.

WARNING

MAINTENANCE OF ACTUATING

CYLINDERS

Applying too much torque while tightening

fittings or other components under pressure may

During preventive maintenance inspections, you

cause catastrophic failure. Such failures can result

inspect actuating cylinders in accordance with the

in injury to personnel or damage to the aircraft.

applicable maintenance requirements cards (MRCs)

for the specific aircraft. Actuating cylinders are

Internal leakage is harder to detect. This leakage is

inspected for leakage and binding. You should clean

usually caused by failure of piston seals, and will

the exposed portion of the piston shaft with a

require repair. Weak, sluggish, or slow movement of

dry-cleaning solvent, and then wipe it with a clean

the actuator usually indicates internal leakage. Refer

cloth moistened with hydraulic fluid. All mounting

fittings are lubricated with specified grease only.

to the appropriate MIM or 03 Manual for repair

11-6