The balanced poppet selector valve has equal

consists of a group of conventional spring-loaded

poppet areas. The poppets will remain in the selected

poppets. The poppets are enclosed in a common

position during thermal expansion of working line

housing and interconnected by passageways to direct

fluid. For this reason, thermal relief valves are

the flow of fluid in the desired direction.

installed in working lines that incorporate balanced

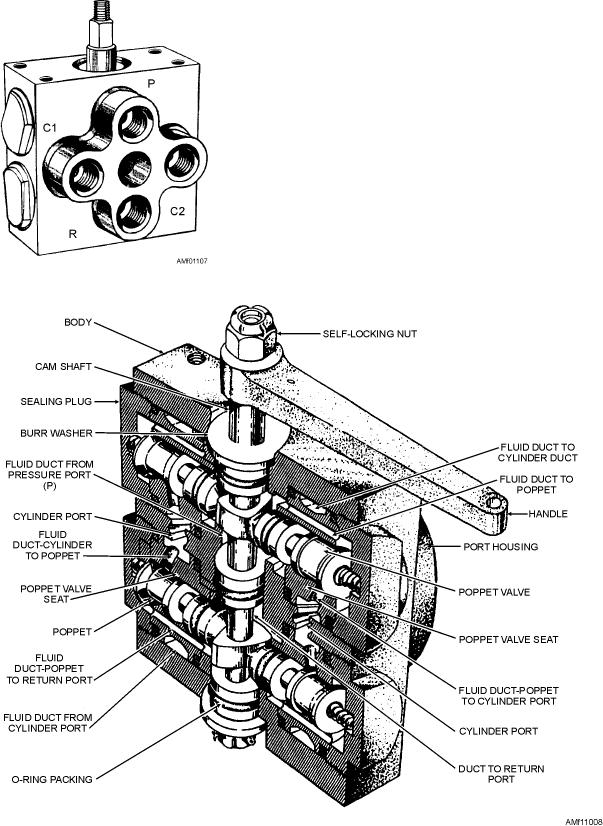

Cams on a camshaft, as shown in figure 11-8,

poppet selector valves.

actuate the poppets. They are arranged so that rotation

Figure 11-7 shows a typical four-port poppet

of the shaft by its controlling lever will open the proper

selector valve. This is a manually operated valve, and

combination of poppets to direct the flow of hydraulic

fluid to the desired port of the actuating unit. At the

same time, fluid will be directed from the opposite port

of the actuating unit, through the selector valve, and

back to the reservoir.

All poppet-type selector valves are provided with a

stop for the camshaft. The stop is an integral part of the

shaft, and strikes against a stop pin in the body to

prevent overrunning. A poppet selector valve housing

usually contains poppets, poppet seats, poppet springs,

and a camshaft.

When the camshaft is rotated, either clockwise or

counterclockwise from neutral, the cam lobes unseat

the desired poppets and allow a fluid flow. One cam

Figure 11-7.--Poppet-type selector valve.

lobe operates the two pressure poppets, and the other

Figure 11-8.--Cutaway view of selector valve body.

11-9