applicable MIM or 03 Manual. After repair or

Malfunctioning selector valves are usually the

adjustment, all valves must be tested for proper

result of foreign particles or damaged parts. A

operation and leakage.

malfunctioning valve should be removed and checked

for free movement of the camshaft. The valve may be

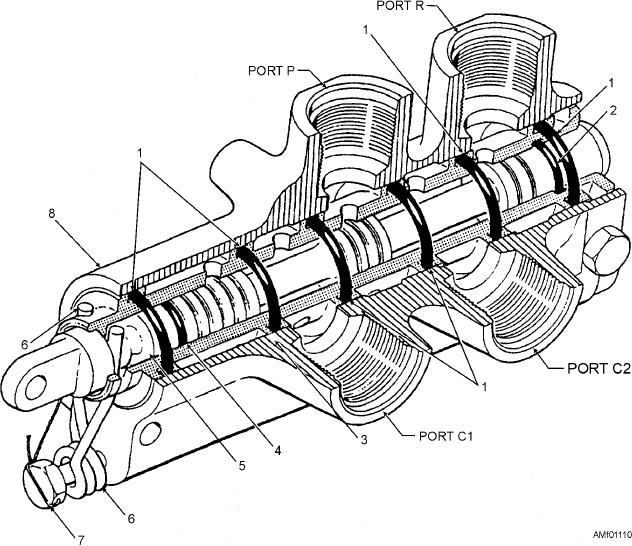

Slide-Type Selector Valve

disassembled and all parts cleaned with clean

hydraulic fluid. O-rings should be replaced while the

The slide-type selector valve is probably the

valve is disassembled.

most durable and trouble-free valve currently in use.

Damaged or worn O-rings may cause both external

Some manufacturers refer to this type valve as a

and internal leakage. A damaged gasket under the

piston or spool type. Figure 11-10 shows a cutaway

sealing plug or the end packing on the camshaft could

view of a typical four-port slide-type selector valve.

cause external leakage. Internal leakage could be

The main parts of the valve consist of a body, sleeve,

caused by damaged center packing on the camshaft, a

slide, detent springs, and the necessary packings and

damaged bottom gasket on the poppet seat, or damaged

gaskets.

O-ring packing on the poppet.

The valve body is cast aluminum alloy. It has four

NOTE: All selector valves that require repair or

fluid ports--pressure, return, and two cylinder ports.

A large bore has been drilled lengthwise through the

adjustment must be done in accordance with the

1.

O-ring gasket

5.

Slide

2.

O-ring packing

6.

Detent spring

3.

Sleeve

7.

Spring retaining bolt

4.

O-ring packing

8.

Body

Figure 11-10.--Slide-type selector valve.

11-11