A check valve, either a poppet or ball, is installed

between the fluid ports of the body, and is held against

a seat by the check valve spring. The seated check

valve spring prevents fluid flow through the valve. The

plunger, driven into the valve by the first unit, unseats

the check.

The balanced sequence valve will not permit fluid

flow in either direction unless the plunger is depressed.

This check valve, with equal working areas (balanced),

cannot be unseated by fluid pressure in either

direction. Thermal relief valves are needed in this

system.

The unbalanced valve can be unseated by fluid

p r e s s u r e b e l ow i t w i t h o u t h av i n g t h e p l u n g e r

depressed. This movement allows thermal expansion

to be relieved. Thermal relief valves are NOT needed

in this system.

Pressure from the selector valve goes directly to

the first unit. To operate the second unit, fluid must

pass through the sequence valve, which it can do only

when the check valve is unseated. On completing its

operation, the first unit depresses the plunger on the

sequence valve, which unseats the check valve and

allows fluid to flow through the valve to second unit.

Thus, the second unit cannot operate until the first unit

operation is complete. In reverse, when contact force

is removed from the plunger, the spring extends it and

the check valve reseats.

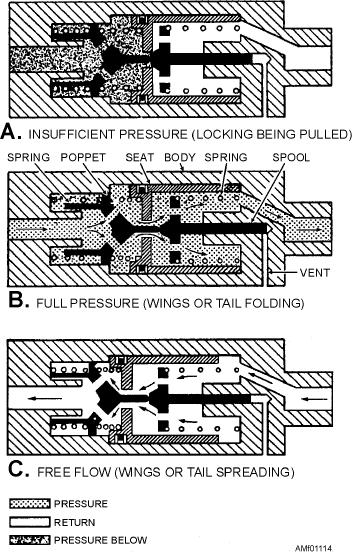

Figure 11-14.--View of priority valve.

Improper adjustment of plungers on the

lockpins and fold actuators. These valves ensure

mechanical-type sequence valve is the most common

lockpin actuation before fold actuator operation. This

cause of trouble. If the adjustment is off, it could cause

completely automatic valve consists of a body

the second unit to operate too soon or not at all. The

containing a spool, seat, poppet, related springs, seals,

adjustment is made either on the plunger of the

and an end cap.

sequence valve or the striker that depresses the

When the wing fold selector valve is in the fold

plunger.

position, it directs fluid both to the wing lockpin and to

Adjustment should be checked at every periodic

the pressure-operated sequence (priority) valve.

inspection. If a valve leaks internally, disassemble,

System pressure drops in the wing fold system because

clean, and inspect the check valve and its sealing

of the amount of pressurized fluid needed to actuate the

surface. Replace faulty O-rings. Internal leakage

lockpins. This lowers pressure below that needed to

could cause the second unit to operate before it should.

open the pressure-operated (priority) valve.

View A of figure 11-14 shows insufficient pressure

Pressure-Operated (Priority) Sequence Valve

to unseat the spool. When lockpins have completed

The pressure-operated sequence valve, also called

their travel, system pressure builds until it overcomes

a priority valve, looks like a check valve externally.

spring tension and causes the poppet to unseat the

Like a check valve, an arrow indicates the installation

spool (view B of fig. 11-14). Fluid then flows freely

position. Figure 11-14 shows this valve installed in a

through the valve to the wing fold actuators.

wing fold system.

View C of figure 11-14 shows the free-flow

During the wing folding cycle, pressure-operated

position of the valve. When spreading the wings,

return fluid moves the seat from the spool compressing

(priority) valves sequence the movement of the

11-16