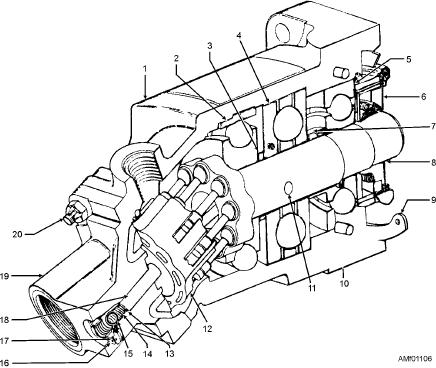

1. Housing

6.

Oil seal assembly

11.

Universal link retainer pin

16.

Retaining ring

2. Drive shaft bearing

7.

Bearing spacer

12.

Cylinder block

17.

Cap

3. Bearing spacer

8.

Shaft and piston subassembly

13.

Spring retaining washer

18.

Cylinder bearing ring

4. Thrust bearing

9.

Retaining ring

14.

Spring

19.

Valve plate

5. Drive shaft bearing

10.

Bearing and oil seal retainer

15.

Cap retaining ring

20.

Valve plate mounting plate

Figure 11-6.--Typical hydraulic motor.

similar, the design and construction may be very

The typical four-way selector valve has four

different.

ports--a pressure port, a return port, and two cylinder

(or working) ports. The pressure port is connected to

SELECTOR VALVES

the main pressure line from the power pump, the return

port is connected to the reservoir return line, and the

Selector valves are used in a hydraulic system to

two cylinder ports are connected to opposite working

direct the flow of fluid. A selector valve directs fluid

ports of the actuating unit.

under system pressure to the desired working port of an

actuating unit (double-acting), and, at the same time,

Three general types of selector valves are

directs return fluid from the opposite working port of

discussed in this course. They are the poppet, slide,

the actuating unit to the reservoir.

and solenoid-operated valves. Practically all selector

Some aircraft maintenance instruction manuals

valves currently in use come under one of these three

(MIMs) refer to selector valves as control valves. It is

general types.

true that selector valves may be placed in this

classification, but you should understand that all

Poppet-Type Selector Valve

control valves are not selector valves. In the strict

sense of the term, a selector valve is one that is engaged

Poppet-type selector valves are manufactured in

at the will of the pilot or copilot for the purpose of

both the balanced and unbalanced design. An

directing fluid to the desired actuating unit. This is not

unbalanced poppet selector valve offers unequal

true of all control valves.

working areas on the poppets. The larger area of the

poppet is in contact with the working lines of the

Selector valves may be located in the pilot's

system; consequently, when excessive pressure exists

compartment and be directly engaged manually

within the working lines due to thermal expansion, the

through mechanical linkage, or they may be located in

poppet will open. This action allows the excessive

some part of the aircraft and be engaged by remote

pressurized fluid to flow into the pressure line, where it

control. Remote-controlled selector valves are

is relieved by the main system relief valve.

generally solenoid operated.

11-8