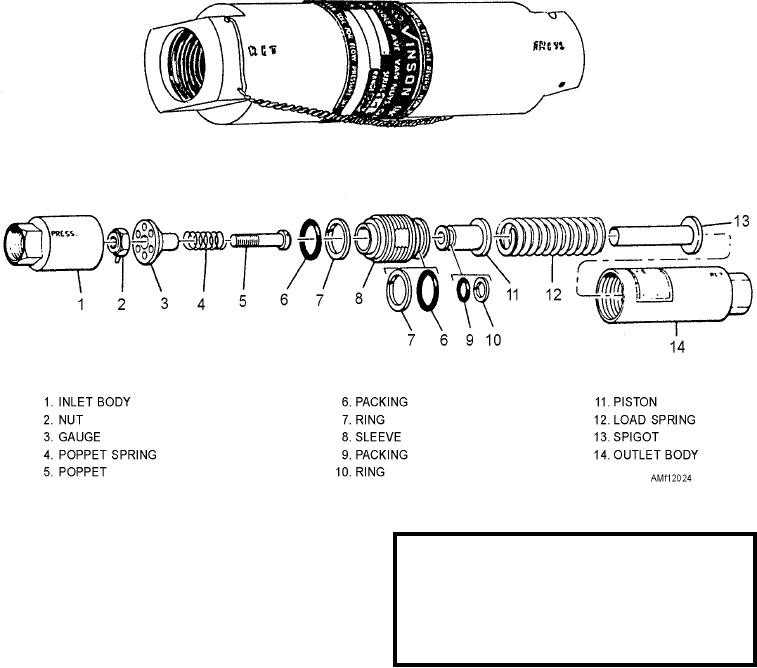

Figure 12-24.--System relief valve.

pressure from being relieved through the main system

CAUTION

relief valve.

Do not attempt to adjust a relief valve while it is

installed on an aircraft. This action will result in an

Figure 12-25 shows a typical thermal relief valve.

incorrect pressure setting. The valve must be

As pressurized fluid in the line in which it is installed

removed and adjusted on a test stand to ensure

builds up to an excessive amount, the valve poppet is

proper pressure settings.

forced off its seat; this allows excessive pressurized

fluid to flow through the relief valve to the reservoir

return line, as shown in view B of figure 12-25. When

SHUTOFF VALVES

system pressure decreases to a predetermined

pressure, spring tension overcomes system pressure

All hydraulic systems do not have shutoff valves

and forces the valve poppet to the closed position, as

incorporated; however, in some systems a shutoff valve

shown in view A.

is installed in the fluid supply line between the

Relief valve maintenance is limited to adjusting the

reservoir and the engine-driven pumps, and other

valve for proper relieving pressure and checking the

places where shutting off the fluid is desirable. These

valve for leakage. If you think a relief valve is leaking

valves, like other valves, may be electrically or

internally, a flexible hose may be connected to the return

manually controlled, depending upon the design of the

port of the valve and the drippings, if any, caught in a

valve.

container. The opening and closing pressure of the

valve may also be checked in this manner provided an

The purpose of shutoff valves differ according to

external source of power is used.

their installation. All shutoff valves control the flow of

fluid; however, they may isolate troubles by shutting

To adjust the opening pressure of a relief valve,

off a complete system or subsystem, or they may

turn the adjusting screw clockwise to increase opening

control the speed a component moves by partially

pressure and counterclockwise to decrease opening

pressure.

closing the valve (manual type).

12-23