3. Eliminates the need of using a test stand to drop

motor from overheating. The reset button will open

and stop the motor when the temperature exceeds 380

check the landing gear and perform operational

10F. If the motor does not restart after cooling, the

checks of other actuating systems.

cover plate over the reset button should be removed and

NOTE: Hydraulic test stands are seldom used on

the reset button reset manually. If the motor still fails to

aircraft that incorporate this type of pump because

start, the motor pump assembly should be replaced.

foreign particles could be transferred from the test

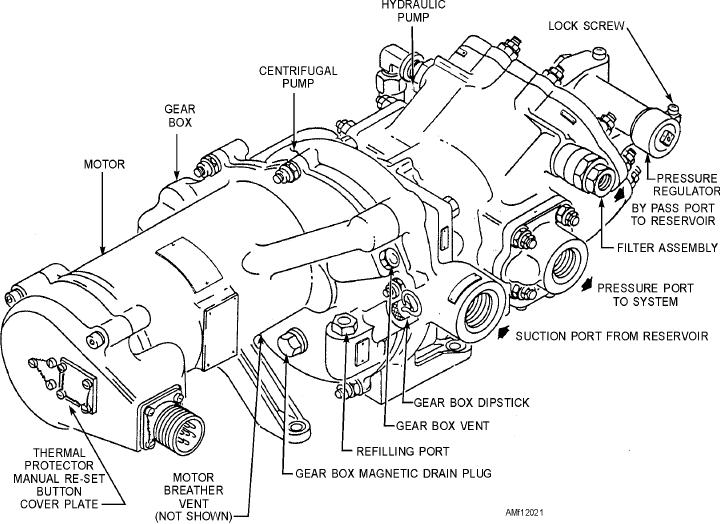

The motor-driven variable displacement pump

stand to the aircraft, thus contaminating the hydraulic

system.

suction line is connected from the reservoir to the

suction port of the pump assembly, where fluid is

4. The pump assembly contains an internal

ported into the center of a centrifugal pump scroll. The

centrifugal boost pump, which provides a

scroll is located between the main pump case and the

positive fluid pressure at the suction port of the

motor reduction gearbox of the pump assembly. See

variable displacement pump.

figure 12-21. The scroll houses a centrifugal booster

pump, which is mounted directly on the main pump

The only disadvantages of the pump are the size of

shaft. The constant-speed motor turns the pump shaft

the complete assembly and its weight. For this reason,

through reduction gears at 3,200 rpm, which is

this type of pump is used in patrol and transport

sufficient to boost the fluid pressure about 15 to 20 psi

aircraft.

above the existing reservoir pressure. The output of

There are other features incorporated in the

this integral pump is directed to two points on opposite

motor-driven variable displacement pump that you

sides of the scroll housing. See figure 12-22.

should know about. A thermal protector manual reset

One delivery point provides a constant flow of

button is installed on the end of the motor, which is

hydraulic fluid for motor cooling through an internal

concealed by a cover plate. See figure 12-21. This

thermal protector is a safety device that protects the

passage. Finned baffle-like passages direct this flow

Figure 12-21.--Motor-driven variable displacement piston pump.

12-19