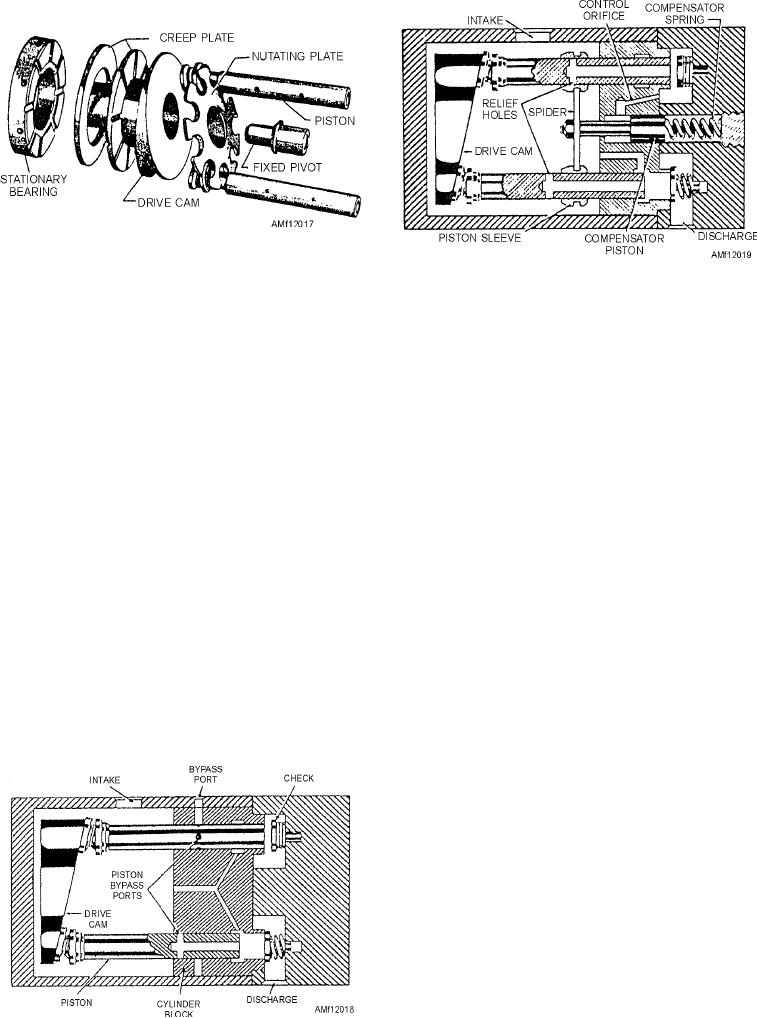

Figure 12-17.--Mechanical drive.

Figure 12-19.--Pressure control mechanism.

check spring pressure closes the check spring when

During normal pump operation, three conditions

piston bypass ports align with the cylinder block

may exist--full flow, partial flow, and zero or nonflow.

bypass passage. The partial vacuum occurring in the

During full flow operation (fig. 12-20), fluid enters the

cylinder during the piston return causes reservoir fluid

intake port and is discharged to the high-pressure side

to flow from the intake loading groove into the

past the pump checks by the reciprocating action of the

cylinder.

pistons. Piston sleeves cover the relief holes for the

Pressure Control.--A schematic diagram of the

entire pressure stroke.

pressure control mechanism is shown in figure 12-19.

During partial flow, system pressure is sufficient

Pressure is bled through the control orifice into the

(as bled through the orifice) to move the compensator

pressure compensator cylinder, where it moves the

stem against the compensator spring force.

compensator piston against the force of the calibrated

control (compensator) spring. This motion,

If system pressure continues to build up, as under

transmitted by a direct mechanical linkage, moves

nonflow conditions, the stem will be moved further

sleeves axially on the piston, thereby varying the time

until the relief holes are uncovered for practically the

during which relief holes are covered during each

entire piston stroke. Relief holes will be covered only

stroke.

for the stroke necessary to maintain pressure against

Fluid flows through the hollow pistons during the

system leakage and to produce adequate bypass flow.

forward stroke and escapes out the relief holes until

Bypass.--The bypass system is provided to

they are covered by the piston sleeves. The effective

supply self-lubrication, particularly when the pump is

piston stroke (delivery) is controlled by the piston

in nonflow operation. The ring of bypass holes in the

sleeve position. During nonflow requirements, only

pistons are aligned with the bypass passage each time a

enough fluid is pumped to maintain system pressure

piston reaches the very end of its forward travel. This

against leakage.

pumps a small quantity of fluid out the bypass passage,

back to the supply reservoir, and provides a constant

changing of the fluid in the pump. The bypass is

designed to pump against a considerable back pressure

for use with pressurized reservoirs.

Maintenance.--Line maintenance of the

Stratopower pump is limited to operational checks, and

checking for leaks and loose fittings. Malfunctioning

pumps should be removed and replaced.

In removing a pump, always maintain its

alignment until the drive shaft is fully withdrawn from

the driving element. Never pick up or carry a pump by

the drive shaft extension.

Figure 12-18.--Fluid displacement.

12-17