one, this plug must be removed and the housing filled

The following installation procedures are typical

examples:

with fluid before the pump is operated. There is a drain

port in the mounting flange to drain away any leakage

1. Place the pump on the aircraft structure

from the drive shaft oil seal.

mounting pad. Connect the pressure and suction lines to

the pump ports and tighten the "B" nuts fingertight.

When the drive shaft is rotated, it rotates the

pistons and cylinder block with it. The offset position

2. Align and install the mounting screws/bolts.

of the cylinder block causes the pistons to move back

3. Tighten the "B" nuts to the correct torque

and forth in the cylinder block while the shaft, pistons,

values.

and cylinder block rotate together. As the pistons move

back and forth in the cylinder block, they draw the fluid

4. Attach the electrical connection to the motor.

in one port and force it out the other. This action

5. Service the reservoir to the proper level.

creates a steady, nonpulsating flow of fluid. Certain

6. Perform operational check according to the

models of this pump are capable of developing up to

applicable MIM.

3,000 psi working pressure.

NOTE: Prior to the installation of hydraulic units,

Constant displacement pumps of this series are

the preservation fluid must be drained and the unit

designed so they can be driven in either direction. The

flushed with clean hydraulic fluid.

direction of rotation of the pump must coincide with

the engine accessory section. The pump rotation can

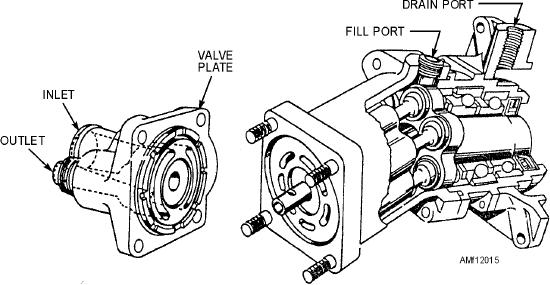

P I S T O N - T Y P E P U M P ( C O N S TA N T

be determined by referring to an arrow on the pump

D I S P L AC E M E N T ) . -- P i s t o n - t y p e c o n s t a n t

housing adjacent to the valve plate. The only change

displacement pumps consist of a circular cylinder

necessary when changing the direction of rotation of

block with either seven or nine equally spaced pistons.

the pump is to rotate the valve plate 180 degrees.

Figure 12-15 is a partial cutaway view of a seven-

piston pump manufactured by Vickers, Incorporated.

Before installation, the pump mounting flange and

shim, if used, must be wiped clean. The pump must be

The main parts of the pump are the drive shaft,

primed by filling the housing with hydraulic fluid

pistons, cylinder block, and valve plate. There are two

through the fill port. The exposed drive shaft spline

ports in the valve plate. These ports connect directly to

should be lubricated. To ensure internal cleanliness,

openings in the face of the cylinder block. Hydraulic

the shipping plugs should not be removed until the

fluid is sucked in one port and forced out the other port

lines are ready for attachment.

by the reciprocating (back-and-forth) motion of the

pistons.

Normally, for repair, the pump should be shipped

t o a n i n t e r m e d i a t e - l ev e l a c t iv i t y ; h ow ev e r,

There is a fill port in the top of the cylinder

replacement of packings and gaskets can be

housing. This opening is normally kept plugged, but it

accomplished in the field. To prevent damage in the

can be opened for testing the pressure in the housing or

case. When you install a new pump or newly repaired

event of the pump binding, a shear section is

Figure 12-15.--Partial cutaway view of piston-type pump.

12-15