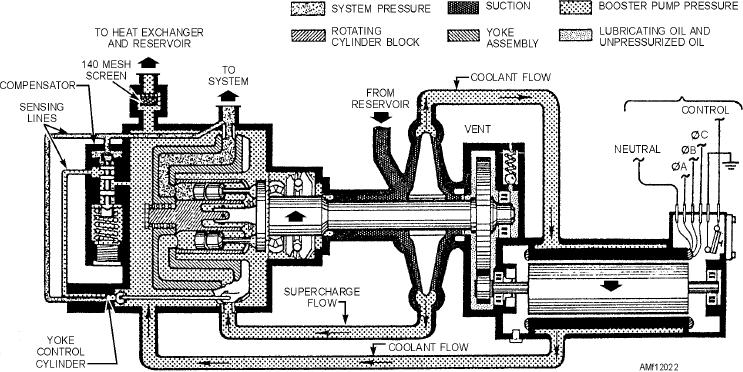

Figure 12-22.--Motor-driven variable displacement piston pump schematic.

around the motor through the hollow-walled motor

provide more or less flow. Whereas engine-driven

case, after which it is directed by an external line into

pumps are generally rated to produce a given pressure

the case of the piston pump. This constant flow

and flow at a nominal drive speed, the electric

through the low-pressure chamber of the main pump

motor-driven pump has a fixed rotational speed and a

cools and lubricates all of its moving parts. It also

special compensating mechanism that enables the

p i c k s u p " b l ow - b y " o i l t h a t e s c a p e s p a s t t h e

pump to provide 6 gpm (gallons per minute) at 2,950 to

high-pressure pump pistons, and is discharged through

3,000 psi. It will provide more flow as system pressure

a coarse-screen filter cartridge installed in the case

drops, reaching a maximum flow of 8 gpm at 2,200 psi.

drain port. The pump's coolant flow is routed through

The accelerated flow enables the system to maintain

the aircraft's heat exchanger and back to the reservoir.

normal speed of many actuators in use simultaneously.

The second delivery point from the integral

Figure 12-23 shows the three phases of pump

centrifugal pump is directed from the centrifugal pump

compensation in a pressure buildup order, starting at

scroll at positive pressure to the intake port of the

low pressure and increasing to full system pressure. As

high-pressure pump. As you can see in figure 12-22,

shown in view (A), the yoke control piston is spring

the Vickers motor-driven variable displacement design

loaded to hold the displacement yoke at its maximum

is similar to other engine-driven designs. The rotating

displacement angle of 30 degrees. This spring is

assembly consists of a baseplate, to which nine piston

opposed by the existing system pressure, which acts at

rods are joined. The assembly turns in a fixed plane.

all times on the "constant horsepower" piston area;

Also turning with it is a cylindrical nine-piston block

however, the hydraulic force will not be sufficient to

fitted inside a nonrotating yoke. The yoke is

move the yoke control piston until the actuating

pivot-mounted to the pump case, and has an offset

pressure (system pressure) builds up to 2,200 psi.

attachment for a compensator piston rod that controls

Thus, the cylinder block will be canted to its maximum

the yoke's attitude. If the yoke is not deflected, the

angle, and the pump will deliver its maximum flow, 8

cylinder block containing the pistons will rotate in a

gpm, when system pressure is less than 2,200 psi.

plane parallel to the baseplate, thus producing no

View (B) of figure 12-23 shows how the yoke

stroke. The yoke can be tilted to displace the pistons,

control piston responds to system pressure fluctuations

reaching maximum stroke when the yoke is tilted 30

in the 2,200 to 2,950 psi range. Assuming that system

degrees from the plane of rotation of the baseplate.

pressure is steadily increasing, the displacement yoke

The pump compensating mechanism receives a

angle will decrease from the 30-degree full

feedback signal of system pressure, and adjusts the

displacement angle to approximately 22 degrees,

pump output by tilting the yoke a prescribed amount to

which will produce 6 gpm at 2,950 psi.

12-20