incorporated in the drive shaft coupling. The coupling

is driven from the engine accessory drive by a splined

may be replaced if the cause of the shearing is known

drive coupling. A shear section is provided in the

and has been remedied. Immediately after removal,

pump drive shaft to prevent damage from overload.

the pump housing should be filled two-thirds full with

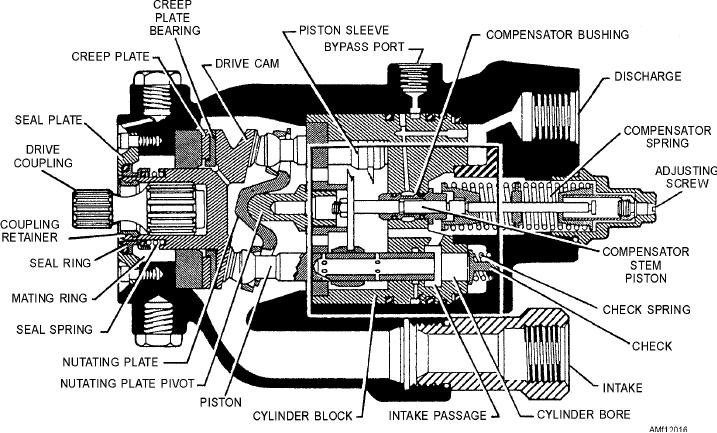

Figure 12-16 shows the internal features of the pump.

hydraulic fluid; the drive shaft couplings should be

Four major functions are performed by the internal

suitably protected by a wood block; and the ports

parts of the pump. These functions are mechanical

securely plugged to prevent the entrance of foreign

drive, fluid displacement, pressure control, and

matter.

bypass.

PISTON-TYPE PUMPS (STRATOPOWER

Mechanical Drive Mechanism.--The

VA R I A B L E D I S P L AC E M E N T ) . -- T h e r e a r e

mechanical drive mechanism is shown in figure 12-17.

s eve r a l m o d e l s o f t h e S t r a t o p ow e r va r i a b l e

Piston motion is caused by the drive cam displacing

displacement pump currently used on naval aircraft;

each piston the full height of the drive cam each

however, all are similar in principle of operation. The

revolution of the drive shaft. By coupling the ring of

pump described here is a Model 65WB06006, rated at

pistons with a nutating (wobble) plate supported by a

3,000 psi and capable of delivering 13 gallons of fluid

fixed center pivot, the pistons are held in constant

per minute at 3,800 rpm.

contact with the cam face. As the drive cam depresses

P r e s s u r e r eg u l a t i o n a n d f l ow c o n t r o l a r e

one side of the nutating plate (as pistons are advanced),

accomplished internally, automatically adjusting

the other side of the nutating plate is withdrawn an

pump delivery to meet the system demands.

equal amount, moving the pistons with it. The two

creep plates are provided to decrease wear on the

Flow cutoff begins at approximately 2,850 psi, and

revolving cam.

it reaches zero (unloads) at 3,000 psi. When the pump

is operating in the unloaded condition, the bypass

Fluid Displacement.--A schematic diagram of

system provides circulation of fluid internally for

the displacement of fluid is shown in figure 12-18.

cooling and lubrication of the pump.

Fluid is displaced by axial motion of the pistons. As

each piston advances in its respective cylinder block

The pump has three ports--the suction port, the

bore, pressure opens the check spring and a quantity of

discharge port, and the drain or bypass port. The latter

port is connected to the reservoir return line. The pump

fluid is forced past. Combined back pressure and

Figure 12-16.--Internal features of the Stratopower pump.

12-16