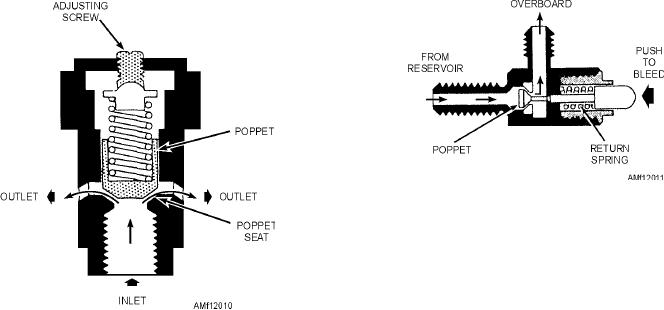

Figure 12-11.--Air bleeder valve.

pressure regulator. The regulator decreases engine

bleed air pressure to a desired working pressure.

As air pressure leaves the regulator, it enters the

reservoir and acts on its piston, which, in turn,

transmits force to the fluid. If malfunction of the

Figure 12-10.--Air relief valve.

regulator causes excessive reservoir air pressure, an air

at a cracking (just open) pressure of 50 psi; the

relief valve will open at a preset pressure and exhaust

reseating pressure is 49 psi. The valve will operate at

excessive air overboard. Fluid under pressure in the

full flow when the pressure reaches 60 psi.

reservoir provides a positive flow of fluid through a

one-way check valve to the suction port of the

All pressure adjustments of relief valves must be

hydraulic pump, thus preventing pump cavitation or

performed on a test bench. You can control valve

starvation.

pressures by adjusting the adjusting screw on the valve

until the proper settings are obtained.

Fluid-Pressurized Reservoirs

AIR BLEEDER VALVE.--During hydraulic

Some aircraft hydraulic systems use fluid pressure

system maintenance, it is necessary to relieve reservoir

for pressurizing the reservoir. The reservoir shown in

air pressure to assist in the installation and removal of

figure 12-12 is a fluid-pressurized reservoir. This

components, lines, etc. An air bleeder valve is

reservoir is divided into two chambers by a floating

incorporated within the reservoir air system to avoid

piston. The floating piston is forced downward in the

disassembly of lines or units. A similar valve may be

r e s e r vo i r b y a c o m p r e s s i o n s p r i n g w i t h i n t h e

incorporated in reservoir return lines to provide a

pressurizing cylinder and by system pressure entering

means for bleeding air from returning fluid.

the pressurizing port of the cylinder.

This type of valve is small in size and has a push

The pressurizing port is connected directly to the

button installed in the outer case. Figure 12-11 shows a

pressure line. When the system is pressurized,

full view schematic drawing of a bleeder valve. The

pressure enters the pressure port, thus pressurizing the

valve is made up of a body, spring, poppet, and push

reservoir. This pressurizes the pump suction line and

button. When the bleeder valve push button is

the reservoir return line to the same pressure. Positive

depressed, pressurized air from the reservoir flows

pressure prevents pump starvation.

through the valve to an overboard vent, until the air

pressure is depleted or the button is released. When the

The reservoir shown in figure 12-12 has five

button is released, the internal spring causes the poppet

ports--pump suction, return, pressurizing, overboard

to return to its seat. In case of malfunction, this type of

drain, and bleed port. Fluid is supplied to the pump

valve is replaced with a new valve.

through the pump suction port. Fluid returns to the

reservoir from the system through the return port.

S Y S T E M O P E R AT I O N . -- D u r i n g n o r m a l

Pressure from the pump enters the pressurizing

operation, the pressurizing air source comes from

cylinder in the top of the reservoir through the

engine bleed air. See figure 12-7. This bleed air is

pressurizing port. The overboard drain port is for the

routed through a poppet-type, one-way check valve to

purpose of draining the reservoir, when necessary,

the chemical drier. The chemical drier conditions the

while performing maintenance. The bleed port is used

air by absorbing its moisture. Conditioned air is then

routed through a poppet check valve to the system air

as an aid in servicing the reservoir.

12-11