hose or hose assembly that is twisted during handling,

hydraulic or pneumatic hose installations. Do not use

removal, or installation can easily cause kinking.

oil of any type on self-sealing hose as an aid to

installation. Compatible oil, approved for the purpose,

PREINSTALLATION P RO C E D U R E S . --

may be used on all other types of fuel, oil, and coolant

Check hose or hose assembly before installing it to

hose installations.

make sure that identification bands and protective

closures are present as required after proof pressure

When you install or handle hose or hose

testing. Inspect hose for proper type and size, and for

assemblies, you can sustain injuries to your hands or

aging (signs of deterioration such as cracks,

damage to the hose if it is kinked. You should take care

discoloration, hardening, weather checking, or fungus).

to prevent situations where injuries or kinking can

Check the braid for two or more broken wires per plait,

occur. A hose that is bent to a smaller radius than

or more than six broken wires per linear foot. Inspect

specified might cause kinking. See table 10-7.

for broken wires where kinking is suspected. Evidence

A preformed hose assembly, or one that has

of internal restriction of tube due to collapse, kinking,

become set-to-shape of its operating position, is

wire-braid puncture, or other damage can be found by

straightened or handled without a protective restraint. A

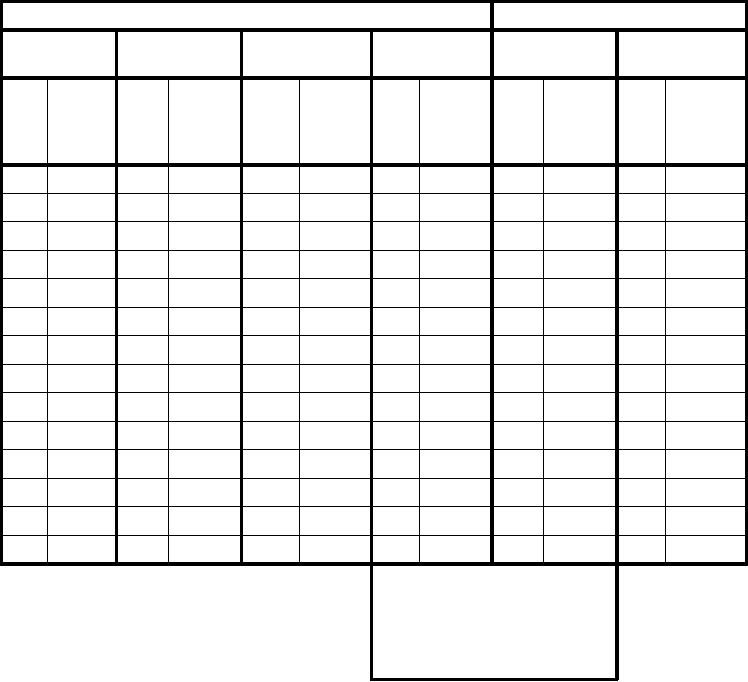

Table 10-7.--Hose Minimum Bend Data

RUBBER HOSE

TEFLON HOSE

LOW PRESSURE

MED PRESSURE

MED PRESSURE

HIGH PRESSURE

MED PRESSURE

HIGH PRESSURE

MIL-H-5593

MIL-H-8794

LTWT MIL-H-83797

MIL-H-8788

MIL-H-27267

MIL-H-83298

MINIMUM

HOSE

MINIMUM

HOSE

MINIMUM

HOSE

MINIMUM

HOSE

MINIMUM

MINIMUM HOSE

HOSE

BEND

DASH

BEND

DASH

BEND

DASH

BEND

DASH

BEND

DASH

BEND

DASH

RADIUS

NO.

RADIUS

NO.

RADIUS

NO.

RADIUS

NO.

RADIUS

NO.

RADIUS

NO.

(INCHES)

(INCHES)

(INCHES)

(INCHES)

(INCHES)

(INCHES)

2

2.00

2

--

2

--

2

--

2

--

2

--

3

2.00

3

3.00

3

1.75

3

--

3

2.00

3

--

4

4.00

4

3.00

4

2.00

4

3.00

4

2.00

4

3.00

5

--

5

3.38

5

2.25

5

3.38

5

2.00

5

--

6

4.00

6

4.00

6

2.50

6

5.00

6

4.00

6

5.00

8

6.00

8

4.62

8

3.50

8

5.75

8

4.62

8

5.75

10

6.00

10

5.50

10

4.00

10

6.50

10

5.50

10

6.50

12

6.50

12

4.50

12

7.75

12

6.50

12

7.75

16

7.38

16

5.50

16

9.62

16

9.00

16

9.62

20

9.00

20

8.00

20

12.00

24

11.00

24

9.00

*16Z

7.38

*16Z

7.38

32

13.25

32

12.50

*20Z

11.00

*20Z

11.00

40

24.00

*24Z

14.00

*24Z

14.00

48

33.00

Z--Designated two stainless steel wire braids.

NOTE:

Bend Radius for MIL-H-600 and

MIL-H-7938 hose shall not be less

than 12 times the inside diameter of

the hose.

10-20