Q10-12. What is the service life of a synthetic rubber

Q10-7. How are locally fabricated hose assemblies

hose assembly that is exposed to the weather,

identified?

fuel, or heat?

Q10-8. What type of cover is used to protect a hose

assembly that is subjected to high

temperatures?

TUBING ASSEMBLIES

Q10-9. All hose assemblies manufactured in a shop

must have what test completed before they are

LEARNING OBJECTIVES: Identify the

installed on an aircraft?

various types of tubing and tubing assemblies.

Recognize materials, tools, equipment, and

Q10-10. What is the first thing you must do when you

testing procedures used in tubing assemblies.

discover a swivel nut leaking?

Recognize maintenance procedures for tubing

Q10-11. What is the acceptance life for a synthetic

assemblies.

rubber hose assembly?

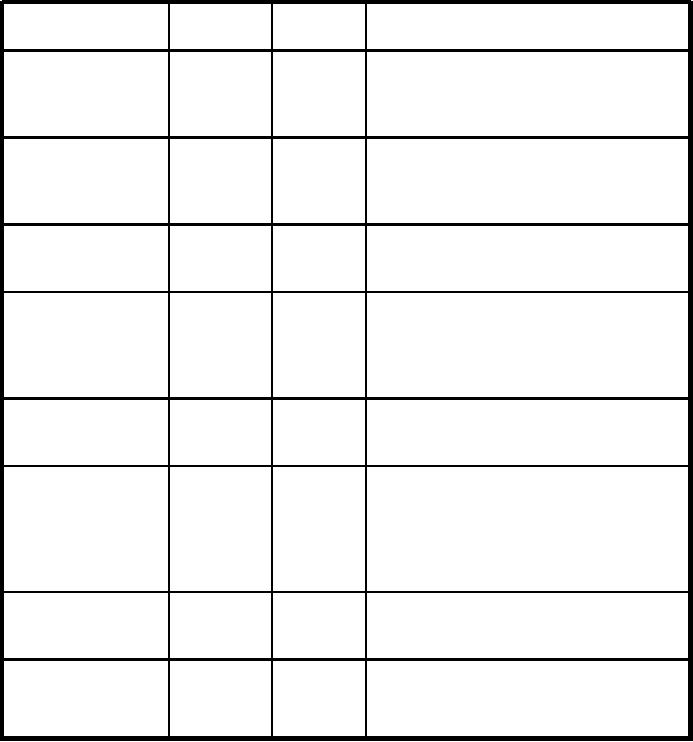

Table 10-9.--Corrosion-Resistant Steel Tubing

Specification

Type

Condition

General Usage and Applications

Tubing Material

MIL-T-7081

6061 A1

Specification covers annealed and three heat-treated

tempers used mostly in O-annealed and T-6. Has

good workability. The 6061-T6 is used in

hydraulic/pneumatic 3000-psi systems.

MIL-T-8506

304

Annealed

Low-pressure applications such as fuel lines.

18-8

Unsatisfactory for high-pressure hydraulic lines. Has

Corrosion-Resistant Steel

high degree of resistance to corrosion.

(CRES)

MIL-T-8504

304

Annealed

Unsatisfactory for welding, brazing or exposure to

temperatures higher than 800F. Used in high-pressure

18-8

CRES

hydraulic/pneumatic systems.

304L

MIL-T-8606

Annealed

Hydraulic/mechanical applications. Has high resistance

to corrosion and high temperatures up to 1500F.

(low carbon)

18-8

321

CRES

Suitable for applications requiring welding/brazing.

347

Type II intended for high-pressure hydraulic

applications, using brazed sleeve joints.

MIL-T-6845

304

1/8H

Used in high-pressure hydraulic/pneumatic systems.

18-8

Unsuitable for welding/brazing applications or

exposure to temperatures above 800F.

CRES

MIL-T-8973

304L

1/8H

Used in high-pressure hydraulic/pneumatic systems

18-8

(low carbon)

assembled with brazed sleeve joints. Suitable for use in

316L

CRES

moderately corrosive or oxidizing environments,

temperatures to 1200F. Weldable.

(low carbon)

321

347

MIL-T-5695

304

1/4H

Used for aircraft structural parts or similar applications

18-8

not requiring sharp bends or flaring. Unsatisfactory for

1/2H

CRES

welding other than resistance weld.

321

Annealed

MIL-T-8808

Aircraft hydraulic quality, used in high-pressure

hydraulic/pneumatic systems. Most often used in these

347

18-8

systems requiring brazing/welding.

CRES

10-24