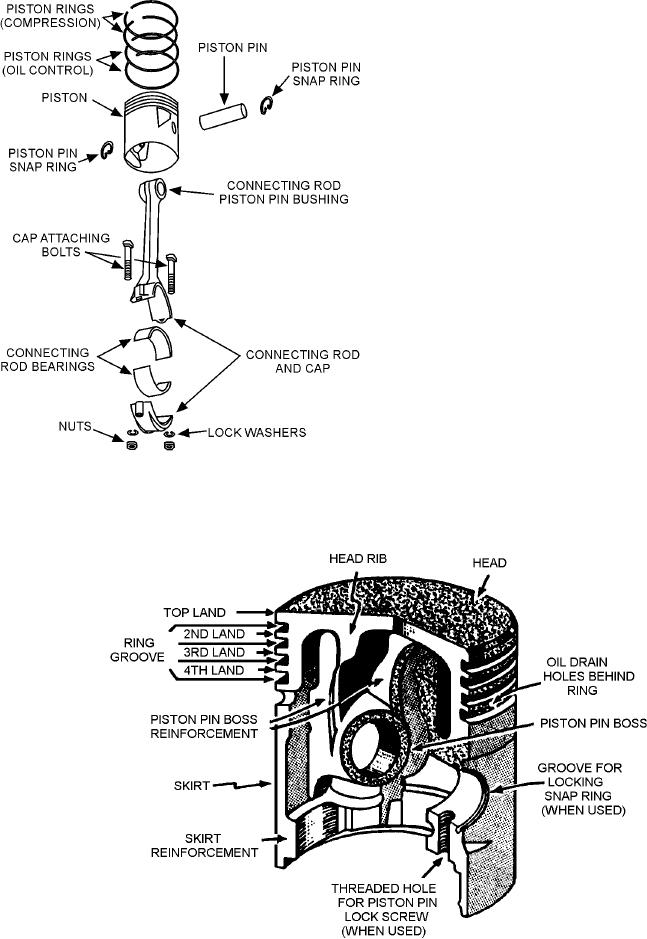

carrier for the piston rings used to seal the compression

in the cylinder. (See fig. 3-25.) Some pistons are

designed to cause turbulence in the cylinder in order to

mix the air and fuel more efficiently.

The piston must come to a complete stop at the end

of each stroke before reversing its course in the

cylinder. To withstand this rugged treatment and wear,

it must be made of tough material, yet be light in

weight. To overcome inertia and momentum at high

speeds, it must be carefully balanced and weighed. All

the pistons used in any one engine must be of similar

weight to avoid excessive vibration.

Pistons are made of gray cast iron or of aluminum

alloy. The former is the heavier and is often used in

slower, heavy-duty engines; the latter is of lighter

weight and is more adaptable to the modern, high-speed

engine. To reduce weight, the head and skirt of the

piston are made as thin as is consistent with the strength

required. Ribs are an integral part of the piston, and

they reinforce the head. The ribs also assist in

conducting heat from the head of the piston to the

piston rings and out through the cylinder walls.

The structural components of the piston are the

head, skirt, ring grooves, and lands (fig. 3-26).

ASf03025

However, all pistons do not look like the typical one

illustrated here. Some have differently shaped heads.

Diesel engine pistons usually have more ring grooves

Figure 3-25.--Piston and connecting rod (exploded view).

ASf03026

Figure 3-26.--The parts of a piston.

3-23