upside down piston, push the ring to about 1 inch from

elasticity after considerable use. Piston rings are often

the bottom of the cylinder. Remove the piston and use a

quite complicated in design, are heat treated in various

feeler gauge to check the clearance. If the clearance is

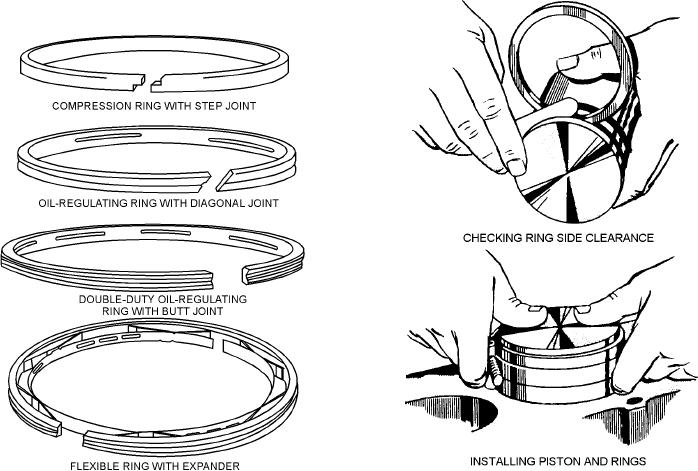

ways, and are plated with other metals. There are two

too large, oversized rings are required. If the clearance

distinct classifications of piston rings: compression

is too narrow, remove the ring and file the ends until the

rings and oil control rings (fig. 3-30).

clearance is correct. To file the ring, first place a file in a

The principal function of a compression ring is to

bench vise; then hold the ring with both hands and

seal in the fuel-air mixture as it is compressed and also

compress the gap while filing. This should ensure the

seal in the combustion pressures as the mixture burns

squareness of the clearance. File only a small amount at

during the compression and power strokes. All piston

a time, checking your clearance often. If you remove

rings are split to permit assembly to the piston and to

too much at one time, the ring is unusable. Clearances

allow for expansion. When the ring is in place, the ends

are specified in the manufacturer's manual and should

of the split joint do not form a perfect seal; therefore, it

be carefully adhered to.

is necessary to use more than one ring and to stagger the

Rings must be fitted also for the proper side

joints around the piston. If cylinders are worn,

clearance (fig. 3-31). This clearance will vary in

expanders are sometimes used to ensure a perfect seal.

different types and makes of engines; however, in the

(See figs. 3-27 and 3-30.)

diesel engine, these rings must be given a greater

The bottom ring, usually located just above the

clearance than in the gasoline engine. If too much side

piston pin, is an oil-regulating ring. This ring scrapes

clearance is given the rings, excessive wear on the lands

the excess oil from the cylinder walls and returns some

will result. If there is too little side clearance, expansion

of it, through slots, to the piston ring grooves. The ring

may cause the lands to break.

groove under an oil ring is provided with openings

through which the oil flows back into the crankcase. In

Connecting Rods

some engines, additional oil rings are used in the piston

skirt below the piston pin.

Connecting rods must be light and yet strong

enough to transmit the thrust of the pistons to the

Prior to installing a new ring, the ring end clearance

must be checked. To check the clearance, first push the

ring about 2 inches into the cylinder. Then, using an

ASf03031

ASf03030

Figure 3-31.--Fitting piston ring and installing piston.

Figure 3-30.--Piston rings.

3-26