flywheel, clutch, transmission, and differential to drive

your vehicle.

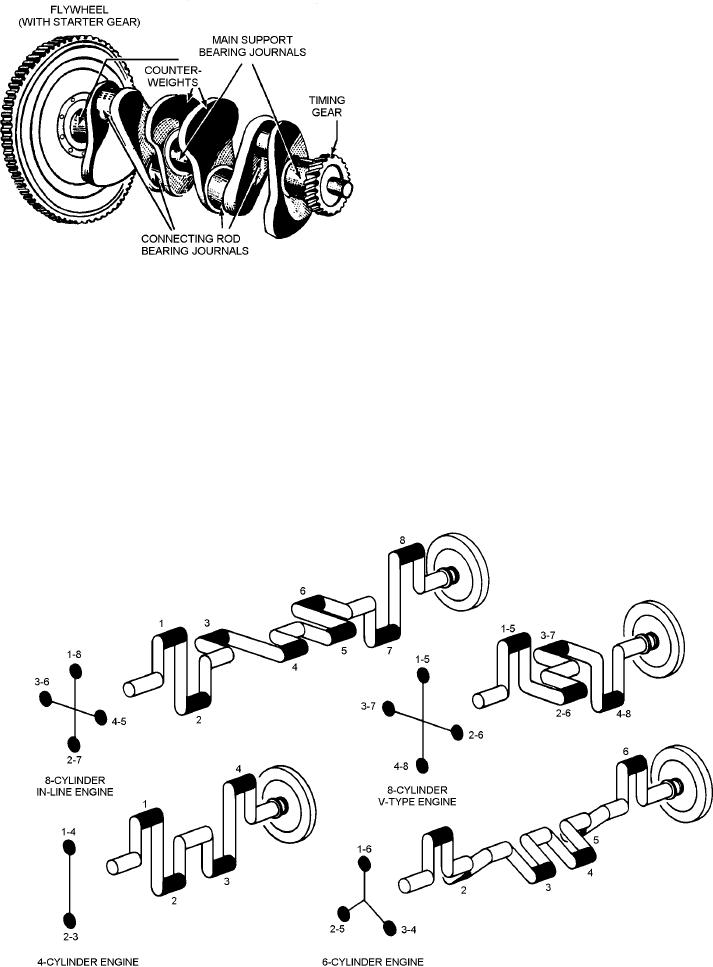

The crankshaft is forged or cast from an alloy of

steel and nickel, is machined smooth to provide bearing

surfaces for the connecting rods and the main bearings,

and is casehardened or coated in a furnace with copper

alloyed with carbon. These bearing surfaces are called

journals. The crankshaft counterweights impede the

centrifugal force of the connecting rod assembly

attached to the throws or points of bearing support.

These throws must be placed so that they counter-

balance each other.

ASf03033

Crank throw arrangements for 4-, 6-, and

8-cylinder engines are shown in figure 3-34.

Figure 3-33.--Crankshaft of a 4-cylinder engine.

Four-cylinder engine crankshafts have either three or

five main support bearings and four throws in one

plane. In figure 3-34 you see that the throws for No. 1

and No. 4 cylinders (4-cylinder engine) are 180 degrees

Crankshaft

from those for No. 2 and No. 3 cylinders. On 6-cylinder

engine crankshafts, each of the three pairs of throws is

As the pistons collectively might be regarded as the

arranged 120 degrees from the other two. Such

heart of the engine, so the crankshaft may be

crankshafts may be supported by as many as seven

considered its backbone (fig. 3-33). It ties together the

main bearings; that is, one at each end of the shaft and

reactions of the pistons and the connecting rods,

one between each of the crankshaft throws. The

transforming their reciprocating motion into a rotary

crankshafts of 8-cylinder, V-type engines are similar to

motion, and transmitting engine power through the

ASf03034

Figure 3-34.--Crankshaft and throw arrangements commonly used.

3-28