The adjustment of valve clearances can generally

pushrod contacts the valve stem. The valve adjusting

be changed by an adjustment screw in the rocker arm or

device, in this case, is in the rocker arm.

by a threaded part of the pushrod (fig. 3-41). A locknut

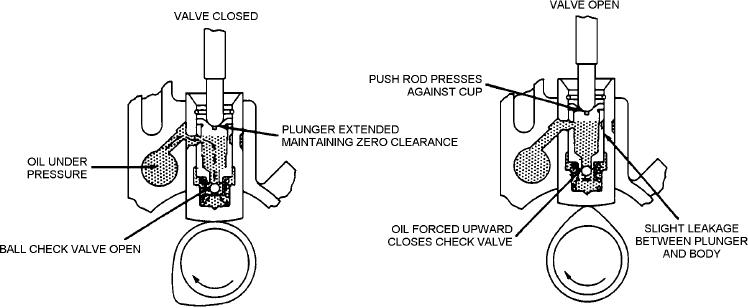

Many engines have self-adjusting valve lifters of

is provided with either device. The manufacturer's

the hydraulic type that operate at zero clearance at all

manual gives you the proper setting and the valve

times. The operation of one type of hydraulic valve

adjustment procedures.

tappet mechanism is shown in figure 3-40. Oil under

pressure is forced into the tappet when the valve is

HYDRAULICALLY OPERATED VALVE AD-

closed, and this pressure extends the plunger in the

JUSTMENT.--On engines equipped with hydraulic

tappet so that all valve clearance, or lash, is eliminated.

valve lifters (fig. 3-42), it is not generally necessary to

When the cam lobe moves around under the tappet and

adjust the valves. They operate with zero clearance (fig.

starts to raise it, there will not be any tappet noise. As

3-40). The engine lubrication system supplies a flow of

the lobe starts to raise the tappet, the oil is forced

oil to the lifters at all times. Hydraulic lifters

upward in the lower chamber of the tappet. This action

compensate for changes in engine temperature, adapt

closes the ball check valve so oil cannot escape. Then,

automatically for minor wear at various points, and thus

the tappet acts as though it were a simple, one-piece

provide ideal valve timing.

tappet and the valve is opened. When the lobe moves

If for any reason the valve mechanism must be

out from under the tappet and the valve closes, the

repaired, an initial adjustment must be made after

pressure in the lower chamber of the tappet is relieved.

reassembling the job. Almost all manufacturers have a

Any slight loss of oil from the lower chamber is then

different procedure for making this adjustment, so

replaced by the oil pressure from the engine lubricating

check the manufacturer's service guide for the engine

system. This causes the plunger to move up snugly

concerned.

against the pushrod so that any clearance is eliminated.

HYDRAULIC VALVE LIFTER SERVICE.--

ADJUSTING VALVE OPERATING MECH-

Hydraulic valve lifters are comparatively simple in

ANISMS.--The intake and exhaust valves are

design. Servicing the lifters requires only that care and

operated by rocker arms and pushrod assemblies

cleanliness be exercised when handling parts.

working off the engine camshaft. In some engines, the

The first indication of a faulty lifter is that it starts

camshaft acts directly on the rocker arm to open the

making a "clicking" noise. A listening rod or an engine

valves. In all cases, it is important that the proper

stethoscope is helpful in locating a noisy valve lifter.

clearance (valve lash) be maintained in the linkage to

You do this by placing one end of the tool against the

compensate for expansion as the engine heats up. Too

particular part of the engine and the other part to your

much clearance causes noise. Also, the valves do not

ear. Move the instrument around the engine until you

remain open long enough. Too little clearance prevents

have narrowed the noise down to a certain area. In an

proper seating and causes burned and leaky valves.

ASf03040

Figure 3-40.--Operation of a hydraulic valve tappet or lifter.

3-32