manufacturer's manual for the allowable maximum

machine together with those of your supervisor until

clearance. When the maximum clearance is exceeded,

you are familiar with the details of grinding.

the valve guide will need further servicing before you

If the tip ends of the valve stems are rough, smooth

proceed with the rest of the valve job.

them by grinding lightly with a special attachment

Servicing procedures will depend on whether the

furnished with the valve refacing machine.

guide is of the integral or the replaceable type. If of the

Before the valve seats are serviced, the valve guides

integral type, it must be reamed to a larger size and a

must be serviced and replaced if necessary.

valve with an oversize stem installed. But if it is of the

VALVE GUIDE SERVICE.--Servicing of valve

replaceable type, it should be removed and a new guide

guides is an important, but often neglected, part of a

installed.

valve job. The guide must be clean and in good

Knurling of the valve guides has become more

condition before a good valve seat can be made. Wear

popular as a method of compensating for wear of the

of valve guides is generally the only trouble you will

valve guides. Knurling is accomplished by inserting a

encounter with them.

special tool in the worn guide attached to an electric

There are several satisfactory methods of checking

drill. This method is not recommended if the guide has

for valve guide wear. One procedure for flathead guide

been worn excessively or previously knurled.

service includes the use of a dial indicator. With the

Valve guides should be removed and replaced with

valve in place, turn the engine so the valve is moved off

special drivers. When working on a valve-in-head

its seat. Install the dial indicator on the block with

engine, you may use an arbor press to remove and

indicating button touching the edge of the valve head.

replace valve guides.

Move the valve sideways to determine the amount of

After the valve guides are serviced and the valve

wear. Another checking procedure involves the use of a

seats are ground, check the concentricity of the two

small hole gauge to measure the inside of the guide and

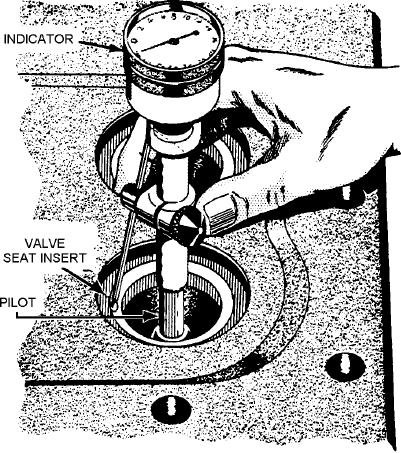

with a valve seat dial indicator (fig. 3-48). Any

a micrometer to measure the valve stem; the difference

irregularity in the seat will register on this dial.

in the readings will be the clearance. Check the

ASf03048

Figure 3-48.--Using a valve seat dial guage.

3-36