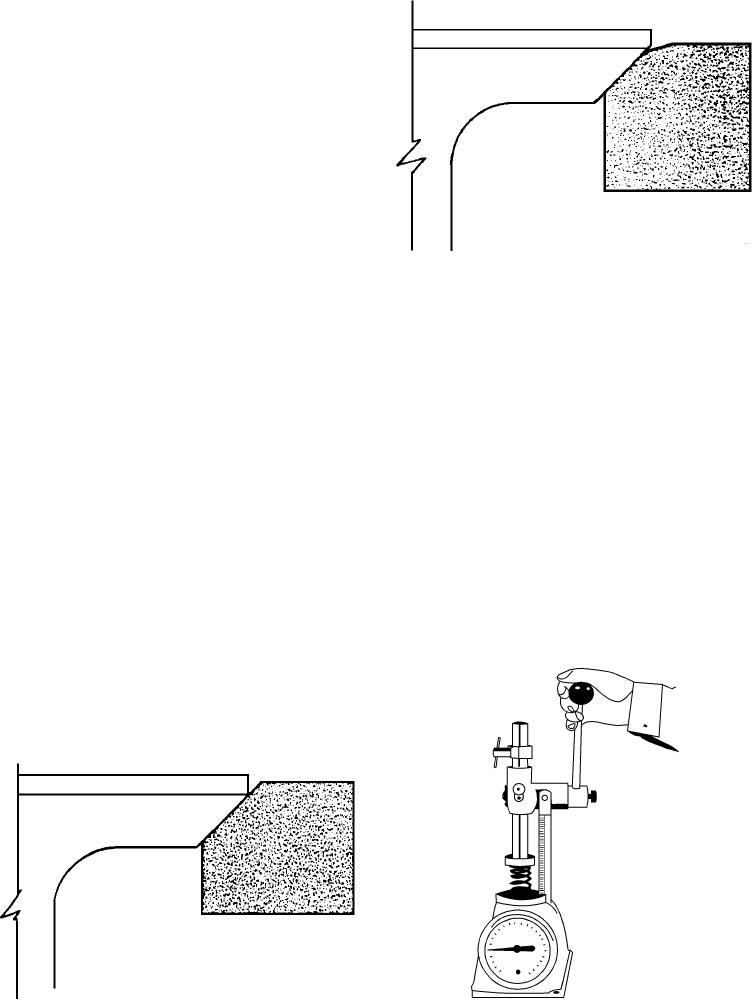

When a great deal of grinding is necessary on a badly

burned or worn seat, a condition such as that shown in

figure 3-53 will occur. When this happens, you should

narrow and center the valve seat by using a 20 degree

stone to cut down the upper portion of the valve seat,

and a 70 degree stone to cut down the lower portion of

the seat. Figure 3-54 illustrates a valve seat that has

been narrowed down from the top of the valve seat.

Grinding with the narrowing stones usually requires

only a few seconds. Check often while grinding so that

you will not remove too much metal.

CHECKING ROCKER ARMS.--After rocker

ASf03054

arms have been removed, they should be inspected for

wear or damage. Rocker arms with bushings can be

Figure 3-54.--Correct valve seat after narrowing seat.

rebushed if the old bushing is worn. On some rocker

arms, the valve ends, if worn, can be ground down on

engine speeds. They also ensure proper valve seating

the valve refacing machine. Excessively worn rocker

and provide a safety factor in case one spring should

arms should be discarded.

break.

The silent lash rocker arm can be disassembled by

Test valve springs for uniformity and strength. For

removing the eccentric retaining pin. If more than one

an accurate test, use a valve spring tester (fig. 3-55)

rocker arm is being disassembled, do not mix the parts;

when one is available. If a valve spring tester is not

make sure all parts go back into the rocker arms from

available, place used springs on a level surface beside a

which they were taken. When reassembling a rocker

pair of new springs. Use any straightedge to determine

arm, make sure the eccentric is installed so that the

irregularities in height. Replace worn out springs with

recessed dot (which is on the side with the smaller

new ones. Unequal or cocked valve springs will offset,

radius) is next to the plunger.

in the assembled job, all the precision that has been put

into the grinding operation.

When reinstalling rocker arms and shafts in the

cylinder head, make sure that the oil holes (in shafts so

When you have reassembled an engine after

equipped) are on the underside so they will feed oil to

reconditioning the valves, make sure the adjusting

the rocker arms. Be sure that all springs and rocker arms

screws are backed off before rotating the engine. A

are restored to their original positions as the shafts are

valve that is too tight could strike and damage the piston

attached to the head.

or the valve, or both.

CHECKING VALVE SPRINGS.--While work-

ing with valves, you may notice that some of them have

more than one spring. These additional springs are

coiled to offset a tendency of the valve to vibrate at high

ASf03053

ASf03055

Figure 3-55.--Valve spring tester.

Figure 3-53.--Valve seat too wide and low in block.

3-38