VALVE SEAT SERVICE.--If a replaceable seat

is badly worn or ground down, replace it with a new

one. Remove the old seat either with a puller or by

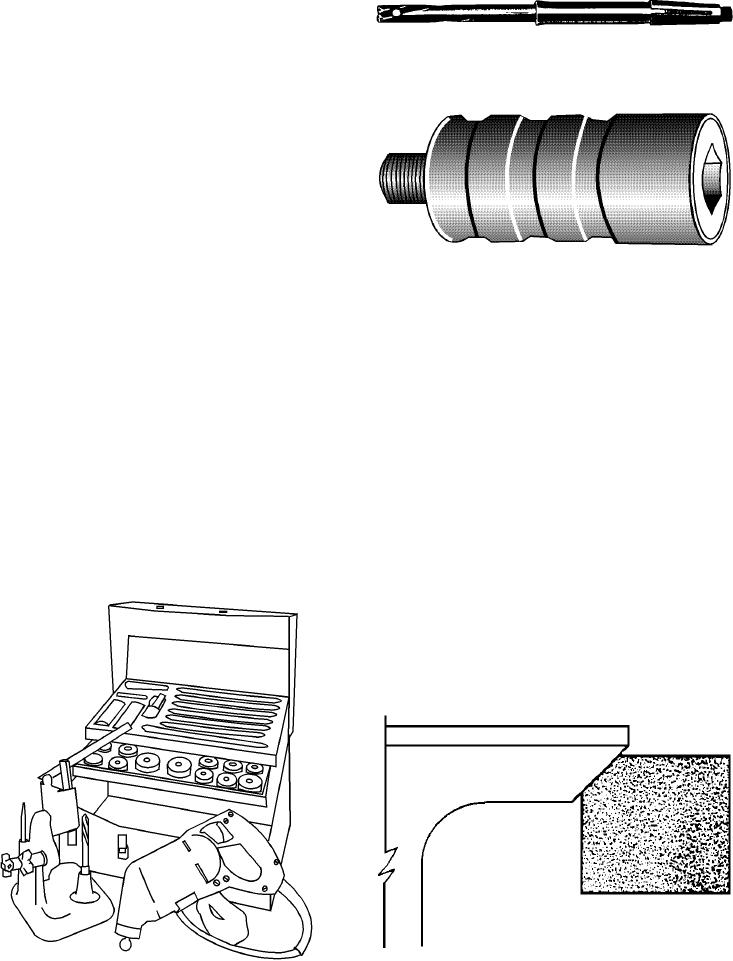

ASf03050

drilling it on two opposite sides, and then breaking it in

Figure 3-50.--Self-centering valve guide pilot.

halves with hammer and chisel. New inserts should be

chilled in dry ice for about 15 minutes to shrink them so

they can easily be driven into place.

In most cases, the valve seats are not replaceable,

so they must be ground. Figures 3-49 through 3-51

illustrate the equipment used in valve seat grinding. Be

sure you know how to operate the kind of equipment

that is in your shop. Study the manufacturer's manual

for specific instructions.

Select the proper size pilot (fig. 3-50) for the valve

ASf03051

guide and insert and lock it into the guide. Wipe the

Figure 3-51.--Valve seat grinding stone sleeve.

valve seat free of carbon dust and oil. Then, with a clean

oily rag, apply a thin film of oil to the pilot shaft.

Use two or more stone sleeves (fig. 3-51) to

operation often and make sure that you do not remove

facilitate seat grinding if the engine block has both soft

any more material than is necessary to get a good seat.

and hard seats or if a high-polish finish grind is desired.

Although recommended, it is usually not necessary

One sleeve may carry a soft seat stone, another a hard

to lap the contact surfaces of the valve and valve seat

seat stone, and a third sleeve a finishing stone.

after they have been ground. Always check your work

All purpose stones are now available that will do all

by testing one or two of the valves. This check can be

of the above grinding jobs with one stone. Make sure

made by spreading a thin coat of Prussian blue on the

the stones are dressed at the proper angle in accordance

valve face or by putting lead pencil marks on the valve

with the engine manufacturer's specifications.

seat. If, when turning a valve on its seat, an even deposit

of the coloring is seen on the valve seat, or the pencil

Only a few seconds are required to recondition the

lines are removed, the seating is perfect. The valve

average valve seat. Check the progress of the grinding

should not be rotated more than 1/8 turn, as a high spot

could give a false indication if turned one full

revolution.

Figure 3-52 shows a normal valve seat, which will

vary according to the manufacturer's specification.

ASf03052

ASf03049

Figure 3-49.--Valve seat grinding equipment.

Figure 3-52.--Normal valve seat.

3-37