ASf03045

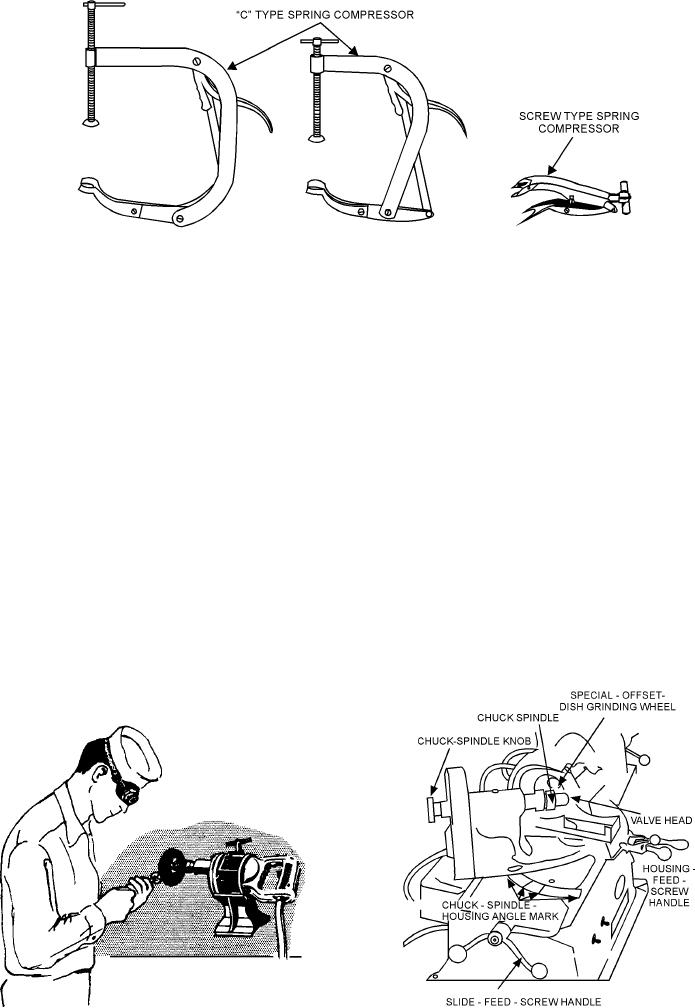

Figure 3-45.--Valve spring compressors for L-head and valve-in-head engines.

After you have cleaned the valves, remove the

compressor (fig. 3-45). Next, clean the valves with a

carbon from the intake and exhaust valve ports. Inspect

wire brush or buffing wheel (fig. 3-46). When using the

closely around the valve ports and cylinders of the

buffing wheel, make sure you wear proper eye

block for cracks and faulty valve seats. Should cracks

protection to prevent wire and other foreign matter

be found, check with your supervisor for the proper

from flying into your eyes.

procedure to follow. After you inspect the cylinder head

Be careful not to interchange the valves. Each valve

for cracks, check the head for warpage, using a

must be replaced in the same valve port from which it

straightedge and a thickness gauge. The water passages

was removed. The valve stem moving up and down in

inside the head should be cleaned if an excessive

the valve guide develops a wear pattern. And, if the

buildup of scale and rust is found. The easiest method is

valves are interchanged, a new wear pattern is

to remove the core plugs and boil the head in a cleaning

developed, causing excessive wear on the valve stem

solution. The alternate method is to scrape the

and guide.

unwanted material loose and then flush with water, air,

To eliminate any confusion, you should devise

or a combination of both. After a thorough inspection

some system of marking the valves to identify them

of the parts, the next step is to resurface the valve face

with the cylinders from which they were taken. The

with a valve refacing machine (fig. 3-47). Clamp the

most common way to identify valves is to place them in

valve stem in the chuck of the refacing machine. Be

a piece of board with holes drilled and numbered to

sure the grinding angle index is set to the angle of the

correspond with the cylinder the valves came from. If

valve head you are about to grind. Follow the operating

any valves are found to be worn or damaged beyond use

instructions of the manufacturer of the refacing

during inspection, replace them with new ones from the

parts room.

ASf03046

ASf03047

Figure 3-46.--Cleaning a valve with a wire buffing wheel.

Figure 3-47.--Valve refacing machine.

3-35