ASf03057

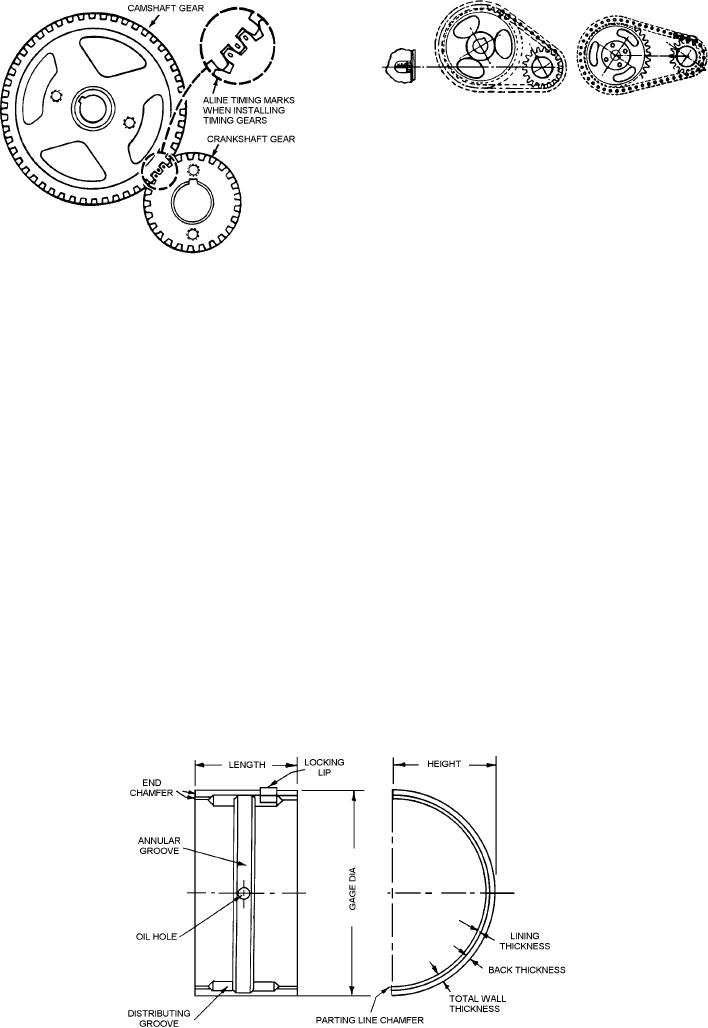

Figure 3-57.--Methods of valve timing with chain drive.

sprockets, as the case may be, of the camshaft and

crankshaft are keyed in position so that they cannot slip.

Since they are keyed to their respective shafts, they can

be replaced if they become worn or noisy.

With directly driven timing gears (fig. 3-56), one

gear usually has a mark on two adjacent teeth and the

ASf03056

Figure 3-56.--Timing gears and their markings.

other a mark on only one tooth. To time the valves

properly, it is necessary only to mesh the gears so that

Following the recommended procedure, adjust the

the two marked teeth of one gear straddle the single

valves to meet the manufacturer's specification. Never

marked tooth of the other.

attempt to adjust valves with solid lifters by "ear." If,

In the case of chain-driven sprockets, the correct

after adjusting the valves with a gauge, there is still

timing may be obtained by having a certain number of

excessive valve-lash noise, do not attempt to tighten the

chain-link teeth between the marks, or by lining up the

adjustment until the noise disappears. To do so may

marks with a straightedge, as shown in figure 3-57. In

result in severe damage to the engine. When valves are

the latter method, the position of the piston is

excessively noisy after adjustment, the components of

determined by markings on the engine flywheel. Some

the valve operating mechanisms should be dis-

engines have timing marks on the crankshaft fan pulley

assembled and inspected for abnormal wear or faulty

if no opening is provided in the flywheel housing.

components.

Always check the manufacturer's instructions when

On any engine on which valve adjustments have

you are in doubt about the method of timing the engine

been made, be sure that the adjustment locks are tight

you are overhauling.

and that the valve mechanism covers and gaskets are in

place and securely fastened to prevent oil leaks.

Engine Bearings

Timing Gears (Gear Trains)

Bearings are installed in an engine where there is

relative motion between parts. Engine bearings are

Timing gears keep the crankshaft and camshaft

called sleeve bearings because they are in the shape of a

turning in proper relation to one another so that the

sleeve that fits around the rotating journal or shaft.

valves open and close at the proper time. In some

Connecting rod or crankshaft (also called main)

engines, sprockets and chains are used. The gears or

bearings are of the split or half type (fig. 3-58). On main

ASf03058

Figure 3-58.--Typical sleeve-type bearing half.

3-39