The precision type bearing is accurately finished to

crankshaft. Connecting rods are drop forged from a

fit the journal and does not require further fitting during

steel alloy capable of withstanding heavy loads without

installation. It is positioned by projections on the shell,

bending or twisting. Holes at the upper and lower ends

which match reliefs in the rod and cap. The projections

are machined to permit accurate fittings of bearings.

prevent the bearings from moving sideways and from

These holes must be parallel.

rotary motion in the rod and cap.

The upper end of the connecting rod is connected to

The semiprecision type bearing is usually fastened

the piston by the piston pin. If the piston pin is locked in

to or die-cast with the rod and cap. Prior to installation,

the piston pin bosses, or if it floats in both piston and

it is machined and fitted to the proper inside diameter

connecting rod, the upper hole of the connecting rod

with cap and rod bolted together.

will have a solid bearing (bushing) of bronze or similar

material. As the lower end of the connecting rod

To maintain good engine balance, connecting rods

revolves with the crankshaft, the upper end is forced to

are carefully matched in sets. When it becomes

turn back and forth on the piston pin. Although this

necessary to remove the connecting rods, make sure

movement is slight, the bushing is necessary because

they are marked so they can be replaced in the same

the temperatures and the pressures are high. If the

cylinder from which they were removed. Most rods are

piston pin is semifloating, a bushing is not needed.

marked at the factory, but if they are not, use a number

punch to mark them in such a way that you will not get

The lower hole in the connecting rod is split to

them mixed.

permit it to be clamped around the crankshaft. The

bottom part, or cap, is made of the same material as the

In addition to the proper fit of the connecting rod

rod and is attached by two or more bolts. The surface

bearings and the proper position of the connecting rod,

that bears on the crankshaft is generally a bearing

the alignment of the rod itself must be considered. That

material in the form of a separate split shell, although,

is to say, the hole for the piston pin and the crankpin

in a few cases, it may be spun or die-cast in the inside of

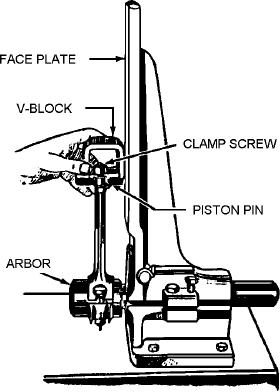

must be precisely parallel. Equipment of suitable

the rod and cap during manufacture. The two parts of

accuracy is available for checking connecting rods.

the separate bearing are positioned in the rod and cap by

(See fig. 3-32.) Every connecting rod should be

dowel pins, projections, or short brass screws. The shell

checked for proper alignment just before it is installed

may be of babbitt metal that is die-cast on a backing of

in the engine. Misalignment of connecting rods will

bronze or steel. Split bearings may be of the precision

cause many hard-to-locate noises in the engine.

or semiprecision type.

ASf03032

Figure 3-32.--Checking connecting rod alignment.

3-27