stem of the valve to be opened is centered under the

circular part of the keyhole slot. The three keyhole

slots are arranged in the sliding-bar to allow the

opening of only one valve at a time. To position the

sliding- bar, loosen the two locknuts and slide the bar

through the oblong slots to the desired position and

tighten the nuts.

SPRAY SHIELDS

Aluminized glass cloth spray shields are

designed to prevent JP-5 from spraying on a hot

surface or electrical equipment, or forming an

atomized mist in the event of a gasket or strainer

leak.

In main and auxiliary machinery spaces, spray

shields are installed on flanged valve (and valve man-

ifold) bonnets, and flanged joints (including gage

lines) on piping containing flammable fluid. For areas

outside main and auxiliary machinery spaces, spray

shields are installed on flammable fluid piping

flanged valve bonnets and flanged joints located in

the direct plane of an electrical switchboard,

electrical equipment enclosure, or motor.

In the event repairs are required to piping or

valve flanges that are covered with spray shields, do

NOT reuse spray shields that have fuel on them.

FILTER/SEPARATORS

There are several different types of filters in use

in the service and transfer systems in the fleet. But,

their principle of operation and hydraulic controls are

similar. The major differences are their physical

shape and flow direction.

Filters are designed to remove 98% of all solids

and 100% of all entrained water from the fuel passing

through them. This is accomplished in a two-stage

operation by two separate faltering media installed

within the filter shell. The first stage consists of a

bank of COALESCING elements, surrounded by a

hydrophobic screen, that performs the function of

removing solids and coalescing water. Coalescing

means the bringing together of fine particles of en-

trained water to form large droplets that then fall out

of the fuel by gravity. The second stage consists of a

bank of SEPARATOR elements that perform the

function of repelling the coalesced water droplets that

were too small to fall out by gravity.

The filter is equipped with a float operated

rotary control valve that will automatically drain the

accumulated water from the filter sump and shut off

the filter discharge if more water accumulates than

can be drained off automatically. This section will

describe typical filter/separators, their operation and

maintenance, and their automatic control devices.

Main Fuel (Service) Filters

The body of the main fuel filter (fig. 4-23) con-

sists of a cylindrically shaped shell with a dome-

shaped head welded on each end. The dome-shaped

heads provide a uniform flow into and out of the

filter. The interior of the filter is divided into an inlet,

fall-out, and outlet (clearwell) by tube sheets.

TUBE SHEET.— The tube sheets are circular

metal bulkheads installed within the filter shell

where the dome-shaped heads are attached to the

cylindrical shell. They are welded throughout their

circumference to form a leakproof partition between

the inlet, fallout, and outlet chambers of the filter.

The tube sheets also provide the means of installing

the filter element mounting assemblies (both

coalescer and separator). Threaded holes, one for

each assembly, are symmetrically arranged over the

tube sheets surface.

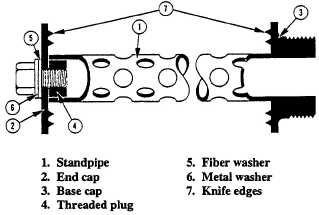

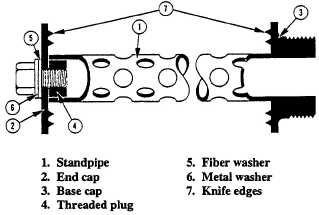

ELEMENT MOUNTING ASSEMBLY.— The

element mounting assembly (fig. 4-24) consists’ of a

perforated metal standpipe about 1 inch in diameter

and 24 inches in length, and an end cap. One end of

the standpipe is fitted with a threaded base cap to

enable screwing it into the tube sheets. The opposite

end is fitted with a threaded plug for attaching the

end cap. The end cap is a metal disk about the same

diameter as the elements.

After the filter element has been placed over the

standpipe, the end cap is secured in place by a

threaded bolt. A metal washer and fiber washer are

provided

Figure 4-24.—Element mounting assembly.

4-27