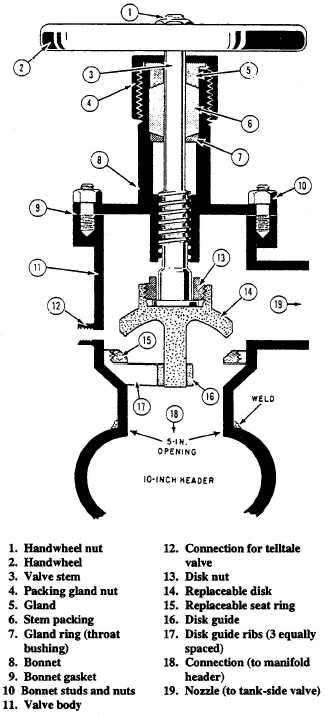

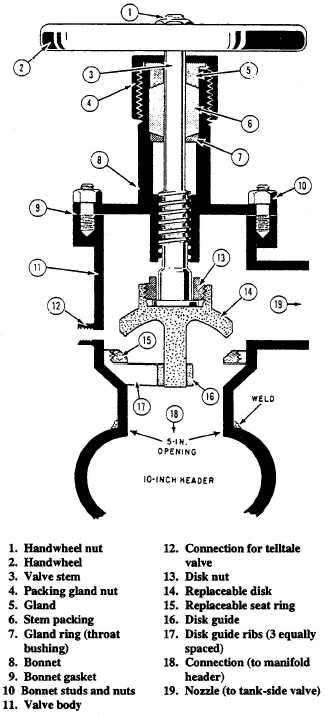

The transfer mainside valves are specially de-

signed globe valves that are welded to the top of the

manifold header (fig. 4-20). They are cylindrical in

shape (about 10 inches in diameter) and consist of a

body and bonnet. The body houses the seat ring and a

guide for the valve disk. Perfect seating of the valve

disk with the seat ring is assured by the disk guide

centered in the base of the valve body. The lower

section of the valve body is welded to the manifold

Figure 4-20.—Transfer mainside valve (cutaway).

header. A hole is machined in the back of the valve

body (above the valve seat) for attaching the nozzle.

On the front of the valve body, a hole is drilled and

tapped (also above the valve seat) for installing the

telltale valve. The bonnet, which provides a working

area for the stem, is bolted to the top of the valve

body. Leakage of JP-5 is prevented by a gasket

between the valve body and bonnet, and packing in

the bonnet packing gland around the stem.

The tankside valve is identical to the transfer

mainside valve, except there is no telltale valve con-

nection and the bottom of the valve body is fitted with

a standard pipe flange. The storage tank fill and suc-

tion tail pipe that the valve serves is bolted to this

flange.

The nozzle is a short section of pipe connecting

one transfer mainside valve to one tankside valve in

parallel so the two valves serve only one tank.

The telltale valves are small, angle type globe

valves installed on the front side of the transfer main-

side valves.

NOTE

Most ships are replacing the telltale

valve with a GAMMON sample connection.

The GAMMON sample connections are less

likely to break or leak, and require no

maintenance.

There is one telltale valve for each set of

manifold valves. These valves are installed on the

front side of the transfer mainside valves, above the

valve seat. They are used to determine the condition

of the valve seats. The telltale valves should be

opened periodically. If fuel leaks from the valve, it is

an indication either the transfer mainside or the

tankside valve is leaking. Both should be inspected as

soon as possible and the leaking valve repaired.

The manifold header drain valve is installed at

the bottom near one end of the header. It is used to

drain the header before maintenance.

A locking device is installed for each of the tank-

side valves. It is typically a bar with a rotating hook

to fit around and locked to the tankside valve handle.

It is arranged so the valve can only be locked in the

closed position. Tankside valves MUST be locked in

the closed position when the tanks are ballasted.

4-24