that other types of valves also may have globe shaped

bodies. Therefore, the name does not always describe

the valve properly.

In a globe valve, the disk is attached to the valve

stem and seats against a seating ring or seating

surface that shuts off the flow of fluid. When the disk

is moved off its seat, fluid can pass through the valve.

Globe valves may be used to limit fuel flow through

the valve (called throttling) by partially opening the

valve to meet the desired flow. Globe valves are most

commonly found on pump discharges, tank mani-

folds, JP-5 purifier discharges, and any other place

where there is a need for throttling fuel flow.

Globe valve inlet and outlet openings are ar-

ranged in several ways and are used to suit the re-

quirements of the flow. There are three common

types of globe valve bodies. In the straight body, the

inlet and outlet openings are in line with each other.

In the angle body, the inlet and outlet openings are at

an angle to each other. The cross globe valve has

three openings instead of two, and is frequently used

in connection with bypass piping.

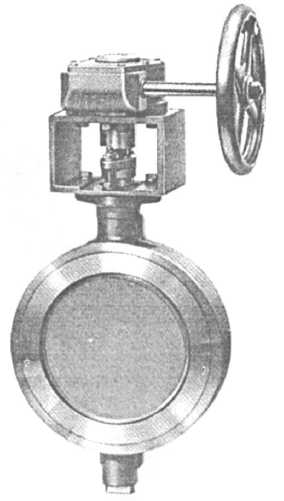

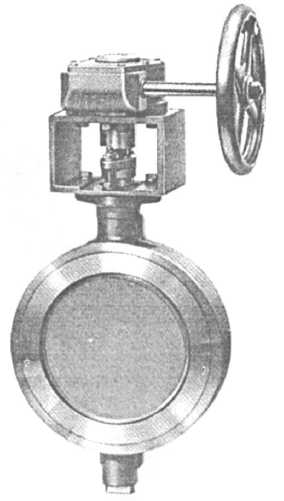

High Performance

Butterfly Valves

The high performance butterfly valve (fig. 4-16)

used in the JP-5 system is designed specifically for

flammable liquids or other hazardous materials. If a

fire guts a piping system or space where these valves

are located, and the fire is hot enough to melt a

special sealing element, a secondary metal sealing

takes place providing effective shut-off of fluid flow

through the piping. No feeding of the fire can take

place.

The high performance butterfly valve has a sin-

gle-piece flexible polymeric seat that is pressure ener-

gized to assure positive shutoff. The seat is so

designed that is compensates for pressure and tem-

perature changes as well as for wear. The design also

allows no metal to metal contact during regular

operations. Also contributing to the valve’s

effectiveness is its offset shaft and eccentric disk

design that impart a camming action to the disk. This

feature causes the disk to swing completely out of

contact with the seat upon opening, eliminating wear

points at the top and bottom of the seat.

This arrangement allows replacement of the

valve seat, if it is ever required, by simply removing

the body insert and then replacing the seat. You do

not have to disassemble the shaft or disk. With no

Figure 4-16.—High performance butterfly valve.

requirement to remove the shaft and disk, repair time

is cut dramatically.

As with the gate valve, the high performance

butterfly valve allows fluid flow in either direction.

High performance butterfly valves are normally used

as isolation valves in distribution piping, but they

may be used nearly anywhere.

Limitorque Valve Operators

On newer CVNs, numerous valves have limitor-

que valve operators. Limitorque valve operators (fig.

4-17) open and close gate and globe valves from a

remote location, usually the pump-room console

(which will be discussed later in this chapter).

Each limitorque, in addition to operating a valve,

also controls and limits the opening and closing travel

of the valve. A torque limit switch on the limitorque

protects all operating valve parts from overload by

4-20