for transfer are designed to pump 200 gpm at 50 psi.

The typical rotary vane pump consists of a cylinder

and head assembly, rotor and shaft assembly, and a

pressure control valve.

CYLINDER AND HEAD ASSEMBLY. —The

cylinder (pump casing) houses and provides a

working area for the rotor and shaft assembly. The

cylinder is machined to form an egg-shaped cylinder

bore. The inlet and discharge ports are cast integrally

with this section of the pump. The pressure control

valve, located on the top of the pump, is cast

integrally with the upper portion of the cylinder bore.

Each side of the cylinder has machined recesses to

ensure perfect fit of the cylinder heads.

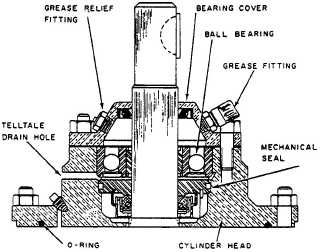

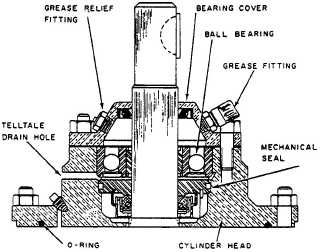

The cylinder heads (fig. 4-1 1), one for each side

of the pump, house the ball bearings and mechanical

seals. An O-ring is installed between the cylinder

heads and the cylinder to prevent leakage.

The ball bearings, located in the bearing housing

within each cylinder head, support and ensure free

rotation of the rotor and shaft assembly, and

maintain the proper clearance between the rotor and

upper position of the cylinder bore. A bearing cover,

with a grease fitting at the top and a grease relief

fitting at the bottom, is bolted to the end of each

cylinder head.

The mechanical seal installed in each head pre-

vents leakage of fluid along the shaft into the bearing

housing. A telltale drain hole, located directly under

the bearing housing, is provided on the underside of

each head. These holes are intended to serve as an

indication of leakage by the mechanical seal.

Figure 4-11.—Rotary vane pump cylinder head.

ROTOR AND SHAFT ASSEMBLY. —The rotor

and shaft is a pressed fit assembly held in place by

tapered pins. The rotor is centered in the upper

portion of the oval shaped cylinder bore. The rotor

has an even number of equally spaced slots that

provide the working area for the sliding vanes. Holes

are drilled through the rotor and shaft, one between

each set of opposing slots, for the installation and

working area of the push rods.

The sliding vanes are made of palamite. Relief

grooves are provided on the forward face of the vanes

to allow the escape of liquid trapped between the

vanes and the slots in the rotor.

NOTE

The vanes must face the direction of

rotation to allow the escape of fluids into the

discharge port.

The pump shaft connects to a gear reducer shaft

by a flexible coupling. The opposite shaft of the gear

reducer is connected to the shaft of the drive motor,

also by a flexible coupling. The purpose of the gear

reducer is to mechanically reduce the motor rpm to

match the rated rpm of the pump.

PRESSURE CONTROL VALVE. —The pres-

sure control valve is provided to prevent buildup of

excessive pressure that might damage the pump or

associated equipment. When over-pressurization

occurs, the valve directs fluid from the discharge side

to the suction side of the pump. It is spring-loaded

closed. An adjustment screw adjusts spring tension

on the valve disc. Relief pressure is determined based

on pump application and piping design. The

adjustment screw has a locknut to lock it at the set

pressure. The pressure control cap is screwed on the

cover to protect the adjustment screw threads.

THEORY OF OPERATION. —The rapid

rotation of the shaft and rotor forces the vanes in

sliding contact with the cylinder bore by centrifugal

force and by push rods. The passage of the vanes

through the lower portion of the cylinder bore draws

fluid into the pump, and at the same time, forces it

out the discharge port. Rotary vane pumps are

positive displacement pumps. This means they will

pump air, which creates a vacuum, causing liquid to

be pulled into the suction side of the pump.

MAINTENANCE. —Maintenance on the rotary

vane pump is done in accordance with PMS and the

4-15